Name: Wire-wound cartridge

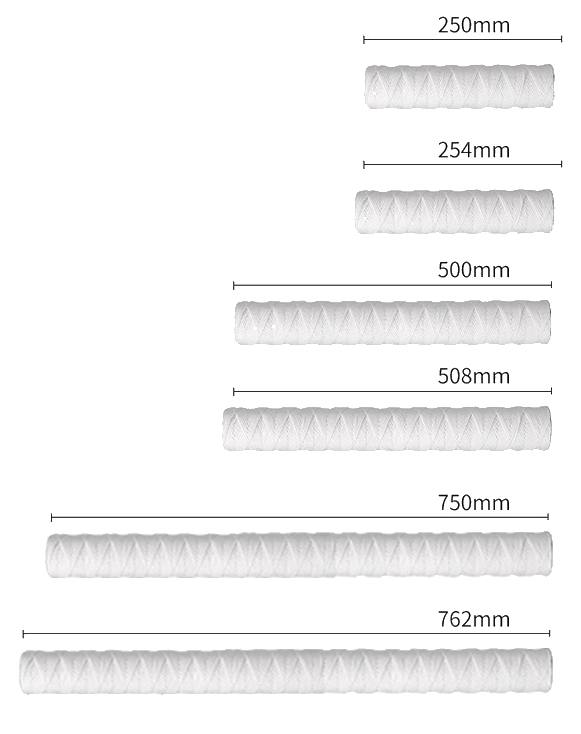

Cartridge length: 10″, 20″, 30″, 40″

Outer diameter of cartridge: Φ60mm, Φ65mm

Inner diameter of cartridge: Φ28mm, Φ30mm

Maximum pressure drop: 0.2MPa

Maximum pressure resistance: ≤0.5MPa

Filtration material: polypropylene PP line, skimmed cotton line, glass fibre line

Filtration precision: 1μm, 5μm, 10μm, 20μm, 30μm, 50μm, 75μm, 100μm

Central skeleton: polypropylene PP skeleton, stainless steel skeleton

Maximum working temperature: polypropylene thread: polypropylene skeleton ≤ 60℃; stainless steel skeleton ≤ 80℃. Skimmed cotton thread: stainless steel skeleton ≤120℃

Can be customized according to different working conditions