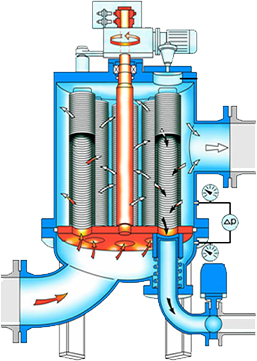

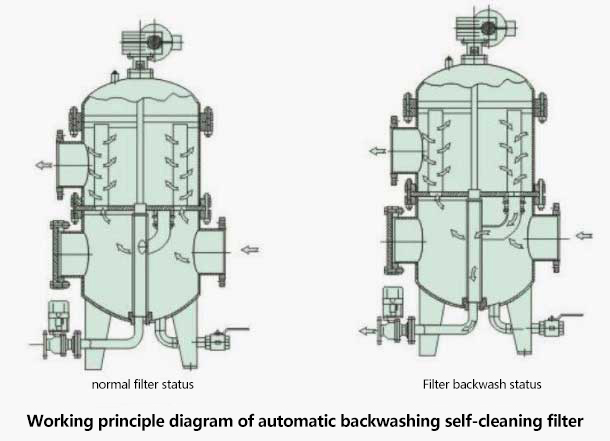

Water from the entrance, first through the coarse filter to filter out the larger particles of impurities, and then reach the fine filter. In the filtering process, the fine screen gradually accumulates the dirt and impurities

in the water, forming a filtering impurity layer, which accumulates on the inner side of the fine screen by the impurity layer, so a pressure difference is formed on the inner and outer sides of the fine screen. When

the pressure difference of the filter reaches the preset value, it will start the automatic cleaning process, during which the clean water supply will flow continuously, the cleaning valve will open, the water pressure

in the cleaning room and the dirt suction device will drop significantly, and through the pressure difference between the filter cartridge and the dirt suction tube, a suction force will be generated between the dirt

suction tube and the cleaning room through the suction nozzle to form a dirt suction process. At the same time, the electric motor drives the suction tube to do spiral movement along the axial direction. The combination

of the axial and rotational movements of the suction tube cleans the entire inner surface of the screen completely. The entire rinsing process takes only tens of seconds. The discharge valve closes at the end of the

cleaning. The filter is ready for the next flushing cycle.