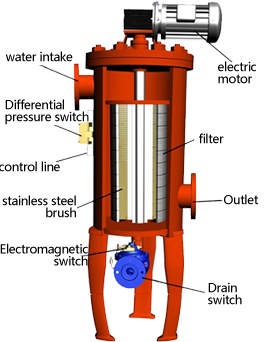

It adopts electromechanical integration design. The automatic self-cleaning filter is composed of main parts such as driving mechanism, control pipeline (including differential pressure switch), main tube assembly, filter

element assembly, cleaning mechanism and connecting flange. The electric controller, control pipeline and drain valve constitute the control part of the filter, which is used to realize the automatic cleaning and discharging

process. The control pipeline consists of accessories such as differential pressure switches, pipe joints and brass pipes. The filter uses stainless steel brushes for conventional products, and other materials of brushes.

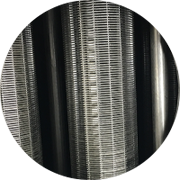

(1) The filtration precision is 100 microns by default, and it can be selected from 50 to 5000 microns, with large filtration area and high dirt-holding capacity, which can be customized by users according to actual

working conditions.

(2)The cleaning method is simple, and the cleaning cycle is electronically monitored, which can realize automatic cleaning and discharging. The parameters in the control system of automatic self-cleaning filter

can be adjusted.

(3)With motor overload protection, which can effectively protect the motor.

(4)It has the characteristics of uninterrupted water supply and no bypass when cleaning and discharging, and the cleaning time is short and the water consumption of discharging is small, not more than 3% of the

total flow.

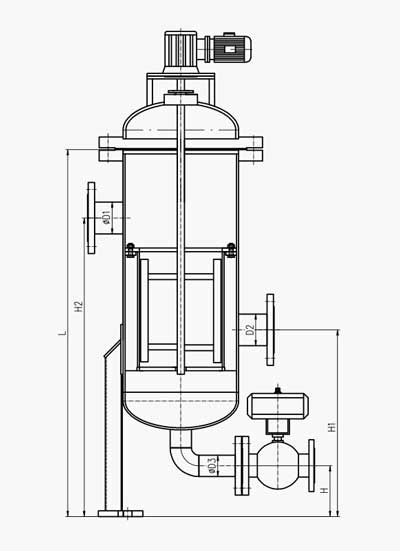

(5) Strong maintenance, easy to install and disassemble. The connection with the user's pipeline is flange connection, and the flange adopts the national standard flange, which has strong universality.