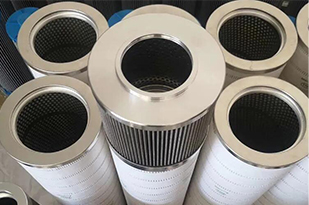

1. The oil filter element of wind turbine gearbox adopts double-effect filter material with pleated structure, high-efficiency glass fiber filter material and stainless steel wire mesh filter material. During normal operation,

the oil is filtered and purified through glass fiber filter material. When poor, filter and purify through stainless steel wire mesh filter material.

2. The filter element is equipped with a special differential pressure valve, which automatically switches the oil to pass through different filter materials under the set pressure difference to ensure that the filter element

is not damaged under the high pressure difference.

3. High-efficiency glass fiber filter material consolidated by resin, high pollution-tolerant space and capacity, fixed pore structure, no filter material fibers migrate and fall off, and the polluted particles intercepted

by filtration will not be unloaded due to pressure difference and flow fluctuation.

4. The glass fiber filter material has a variety of filtration precisions to choose from, and the interception and removal of polluting particles is fast and efficient.

5. The high-strength polyester support material and outer wrapping structure of the upstream and downstream of the filter element ensure the strength of the filter element and the stability of the filter area.