Filtration status

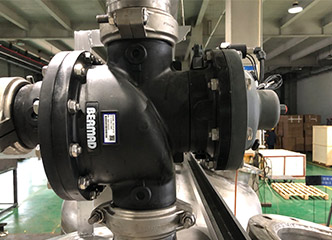

The shallow sand filter consists of a number of filtration units combined side by side. When the system is in the filtering state, the unfiltered water is evenly distributed through

the unique water distributor developed by the company, and the water passes through the filler layer (refined homogeneous quartz sand) in the filter in a laminar flow. When the water flows through the packing layer,

impurities are trapped in the packing layer. There are several evenly distributed water collectors at the bottom of the filter to collect and draw out the filtered water evenly. The level flow filtration enables the

filter to filter at high flow rates and still achieve a good filtration effect.

Backwashing status

As impurities continue to accumulate in the packing layer, the internal pressure head loss will continue to increase. When the inlet and outlet head loss reaches the set value, the

system will automatically activate the differential pressure device to convert it to the backwashing state, and when this backwashing is over, the hydraulic valve will change the direction of water supply to achieve

backwashing one by one, which is more convenient to clean the accumulated impurities. When the system is in the backwash state, filtration still continues, where the standard unit sand cylinder to be backwashed is not

filtered, but the other standard unit sand cylinders in the system are still filtering. The filtered clean water is partly used to backwash the standard unit grit cylinders and the rest is still sent to the customer.

The backwash effluent is discharged through the backwash drain in the hydraulic valve. In the high efficiency filtration system for high speed sand cylinders, the special collector design allows the fillers to be scrubbed

against each other, maximising backwashing efficiency and reducing the amount of backwash water required (clean water), while at the same time backwashing without running material. A standard unit of sand cylinder backwashing

for 3 minutes, backwashing is completed, the standard unit of sand cylinder internal pressure head loss reduced to a reasonable range, the pressure setting device to give a recovery signal, hydraulic valve back to the

filter state, the next standard unit of sand cylinder is ready to enter the backwashing state, the system can also be controlled by time backwashing, the default 4 hours backwashing once, according to the working conditions

of the site to adjust the time, dual system control is not divided into primary and secondary, which first.