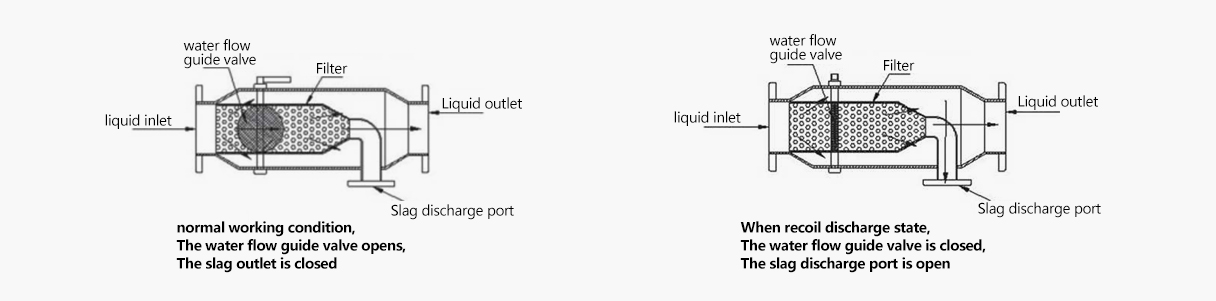

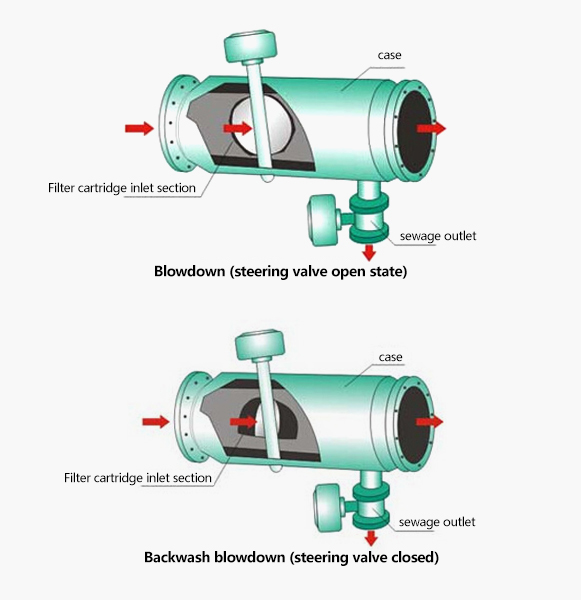

Under normal circumstances, the steering valve is opened and the water is filtered through the filter cartridge and discharged from the outlet, when the drain valve station is opened, the total flow of liquid through the

filter increases, the flow rate increases, impurities that stick to the wall of the filter are flushed, impurities are discharged from the drainage outlet, when the steering valve is closed and the drainage valve is

opened, the water is forced to enter the outside of the filter cartridge from the inlet section mesh of the filter cartridge, most of it flows out from the outlet, and part of it enters the inside of the filter cartridge

from the outside of the filter through the mesh of the impurity collection section, which produces a backwash to the filter cartridge and achieves the effect of flushing the impurities that stick to the mesh from the

outside of the filter cartridge, impurities are still discharged through the drainage outlet.