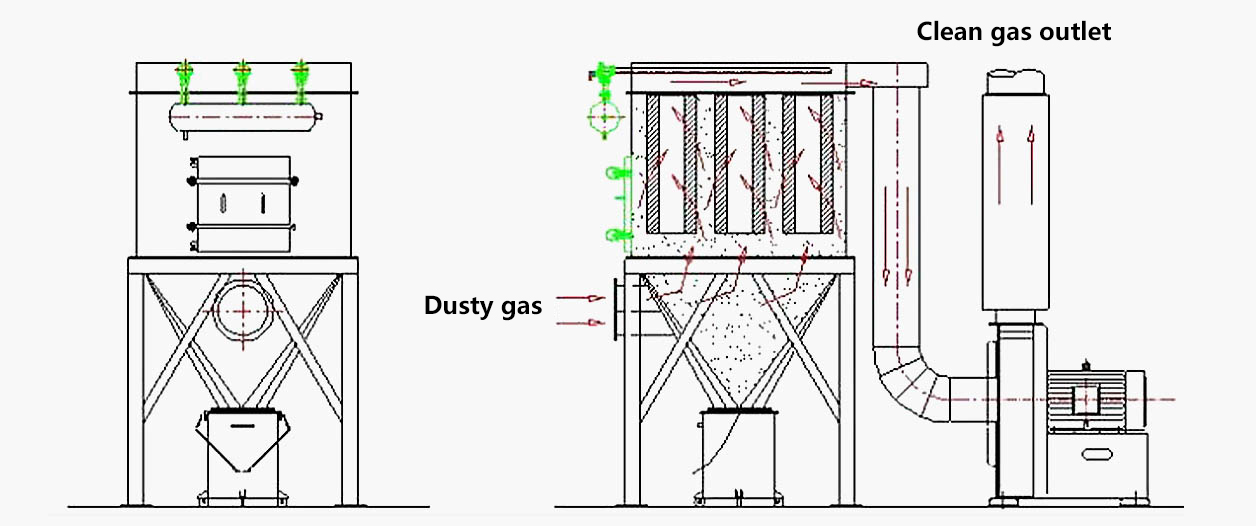

The main body is divided by a tube sheet into two parts.

The lower body is called dirty air plenum, the upper body is called clean air plenum.

The lower body includes an inlet which is connected to flexible suction pipes which carry the dirty air from the source, At the bottom is the hopper which is fitted with a rotary air lock system for continuous discharge

of the dust particles.

The upper body includes the main filtration system.

It includes the rows of filter cartridge, each cartridge is attached to the tube sheet.

Above the tube sheet in the upper body is the cleaning system of the machine. It includes the rows of blowpipes, each blowpipe is drilled with holes and connected to the air reservoir which has solenoid valveattached to it.

The upper body also includes the outlet which is connected to a series of pipe, used to carry the filtered air.