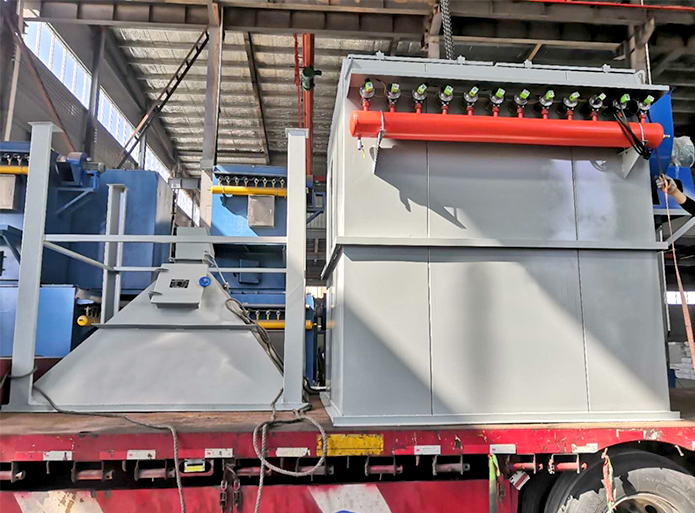

The dirty air enter the system through the inlet and pass through the filter bags.

Due to the use of baffle plate, the heavy particles fall down into the hopper, the lighter particles get deposited on the exterior surface of the filter bags, only allowing the clean air pass through the filter bags up to the clean plenum. The clean air

is discharged from the outlet. This is the general process take place in this system.

When a certain level of deposited dust is reached on the filter bag, a pressure is created, and it is detected by the gauge fitted on the machine. And this starts the process of cleaning of the filter bags.

Air stored in the reservoir is released which is carried by the blowpipes.

The high-pressure air is released into the filter bags one row at a time.

The air passing through the filter bags releases the deposited dust and clean the bag, the dust then fall off into the hopper. This process takes place at regular intervals of time, and this allow the filtration process runs smoothly. This is how a pulse

jet dust collector works.