In the ever-progressing world of industrial technology, industries are constantly seeking effective, reliable, and efficient dust control solutions. Positioned at the forefront of this innovation is the Single-Machine Pulse Jet Bag Dust Collector, a specialized technology that marries high efficiency with convenience and flexibility.

Particularly suitable for industries such as chemical processing, mining, power plants, cement manufacturers, and mechanical workshops, this dust collector is an environmental ally. It is this wide range of applications that sets the Single-Machine Pulse Jet Bag Dust Collector apart from others.

The prowess of the Single-Machine Pulse Jet Bag Dust Collector lies in its core operating principles. Outfitted with high-pressure (0.5 - 0.7Mpa) high-flow pulse valve filter bag jet cleaning technology, this equipment is revered for its significantly high dust removal kinetic energy, and in turn, remarkable dust removal efficiency. It offers a compact structure that is not only lightweight but also easy to install and operate.

Another feather in the cap of the Single-Machine Pulse Jet Bag Dust Collector is its customer-oriented model. Users can customize their unit to match their unique working conditions, ensuring optimized operation specific to their industry.

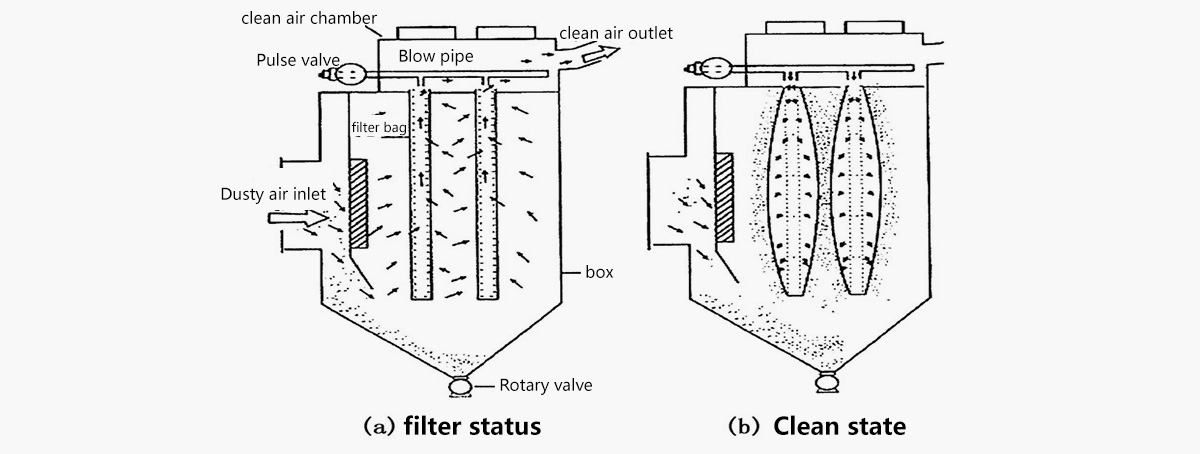

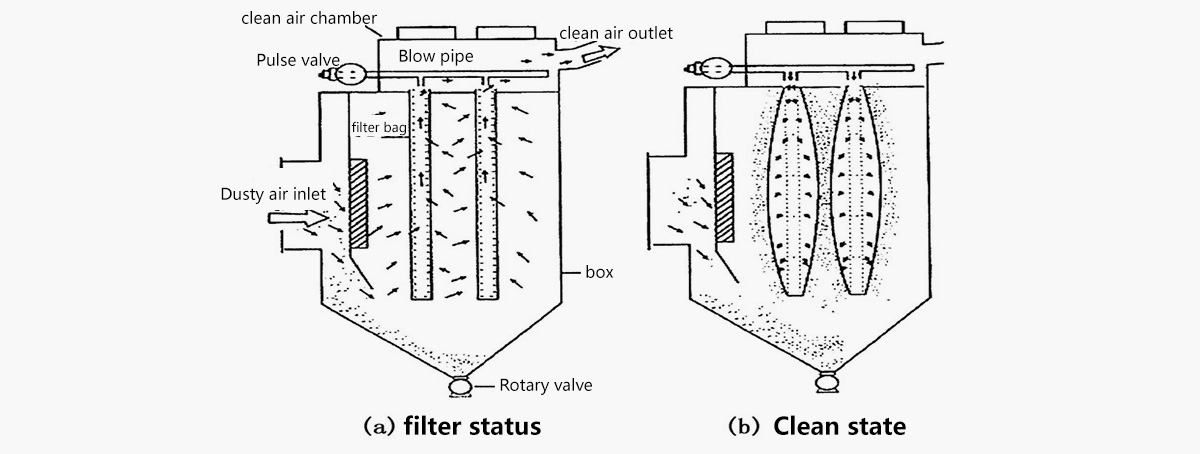

The equipment’s operation process is simple yet effective. Dust-laden gas enters the ash hopper from the air inlet, transitions through the filter bag to the clean air chamber, and is then discharged out the exhaust port by the fan. Throughout this process, the dust collector’s resistance is kept under 1200PA, ensuring efficient ongoing work. The dust accumulation process ultimately triggers the necessary cleaning process, powered by the pulse valve, which successfully shakes off the accumulated dust.

Equipped with these noteworthy features, it's no surprise the Single-Machine Pulse Jet Bag Dust Collector has a broader application. From mechanical equipment workshops and cement plants to steel plants and carbon foundries, this equipment has proven capability in handling air particles, smoke pollution, and ultra-fine dust air.

What truly distinguishes this gem of dust removal technology is an impressive list of advantages. High dust removal efficiency exceeding 99.9%, flexibility and convenience of on-spot dust collection and treatment, low energy consumption, longer service life, minimal footprint, and low investment cost are only a few of its remarkable benefits.

Completing this impressive profile is the Single-Machine Pulse Jet Bag Dust Collector's notable feature - the use of pleated filter media. This increases the filter area, making the dust collector more compact. By allowing increased dust capture on a smaller footprint, this original, thoughtful design makes the equipment more efficient and a perfect fit for virtually any industry.

All these superior features, combined with unique customization options, safe, and reliable operation, explain why the Single-Machine Pulse Jet Bag Dust Collector is a favored solution in various industries globally. For any entity seeking a specialized lens into the world of efficient environmental protection, dust control, and technological advancement – the Single-Machine Pulse Jet Bag Dust Collector stands as a robust and reliable choice.

By harnessing the power of these advanced pulse jet bag dust collectors, industries can help protect our environment while enhancing their process efficiency – a win for them, their workforce, and our planet.

The Single-Machine Pulse Jet Bag Dust Collector, a game-changing technology where high dust removal efficiency meets versatility and customer-specific customization, indeed a revolutionary stride for industries and our environment.

Customization Feature in Different Industries:

When it comes to the Single-Machine Pulse Jet Bag Dust Collector, the customization feature serves as a substantial advantage across several industries. Different industrial settings have unique operational conditions, including the type of dust, operating temperatures, environmental factors, and spatial limitations.

Adaptability: Users can adapt the dust collector to the specific types of dust they deal with, optimizing the dust collection and filtration process. This ensures that the dust collector works efficiently, no matter whether it's collecting fine dust from a mining operation or heavier particles in a cement plant.

Specific Needs: Industries that require operation at higher temperatures can choose suitable materials that can withstand these conditions. Moreover, those who work with harmful chemicals can ensure the dust collector can handle the corrosive nature of these chemicals.

Space Optimization: For industries operating in smaller spaces, the dust collector can be customized to fit the available area without compromising its dust collection efficiency.

Efficiency Maintenance: By customizing their dust collector as per their specific requirements, businesses can better maintain operational efficiency, reduce operational costs, and extend the lifecycle of their dust collector.

Use of Pleated Filter Media:

In the Single-Machine Pulse Jet Bag Dust Collector, the use of pleated filter media offers key advantages:

Increased Surface Area: Pleated filter media substantially increase the surface area available for filtration. This means a higher capacity for dust capture while maintaining a compact overall size.

Efficiency: This design boosts the dust collector's overall efficiency, supporting its critical role of filtering out harmful dust particles of various sizes from the air, including extremely fine sub-micron particles, which can otherwise pose significant health risks.

Longevity: The pleated design also improves the longevity of filter bags by reducing the physical stress on any single point during pulse jet cleaning. This leads to extended filter life and less frequent bag changes, driving down maintenance costs and preventing operational downtime.

Energy Saving: Through effective filtration, pleated filter media promotes better airflow and requires less energy, contributing to the dust collector's energy-efficient operation.

Versatility: Pleated filter bags are more versatile, accommodating for a range of air volumes, and are therefore suitable for various applications. This is a critical factor in achieving optimal dust collection performance in diverse industrial settings.

Overall, the customization feature of the Single-Machine Pulse Jet Bag Dust Collector and the use of pleated filter media provide a powerful combination, enabling businesses across various industries to achieve efficient, effective dust collection tailored to their unique needs.

Customization Feature for Industries with Limited Space:

In industries with limited space, the customization feature of the Single-Machine Pulse Jet Bag Dust Collector is a tremendous advantage. By allowing users to tailor the size and configuration of their dust collector to fit their work environment, it ensures optimal use of available space.

Size Customization: An industry with limited space can order a smaller-sized dust collector that fits better within the confines of their operational space without losing efficiency.

Shape Flexibility: Depending on the layout of the workspace, the dust collector can be customized to have unique shape configurations, enabling it to fit into corners or along walls, thereby optimizing the utilization of space.

Compact Design: Despite their compact size, the dust collection and filtration efficiency is not compromised thanks to innovative features like pleated filter media, which provides a large filtration area within a compact structure.

Energy Efficiency of Pleated Filter Media:

Pleated filter media contribute significantly to the energy efficiency of the Single-Machine Pulse Jet Bag Dust Collector:

Improved Airflow: The pleated design essentially increases the filter media's surface area in the same available space, thereby allowing for better airflow. This put less strain on the dust collector system, thus reducing the energy usage.

Reduced Cleaning Frequency: The larger surface areas of the pleated filter media capture and hold more dust before cleaning is required. Fewer cleaning cycles translate to less use of compressed air in pulse jet cleaning, saving energy.

Heat Conservation: Pleated filter bags are capable of conserving more heat due to their compact design, which can reduce the energy needed for certain processes in industrial systems.

Reducing Maintenance Costs through Customization:

The customization feature of the Single-Machine Pulse Jet Bag Dust Collector plays a significant role in reducing maintenance costs for businesses:

Operational Efficiency: By providing a unit that has been specifically tailored to a business's unique requirements, the dust collector will operate at optimal efficiency, reducing wear and tear on the system and extending the lifecycle of the machine.

Filter Efficiency: Tailoring the filters to the type of dust generated in a specific industry can enhance filter efficiency, resulting in longer filter life and less frequent replacements, thus saving on maintenance costs.

Downtime Alleviation: Since the customized dust collector is geared to handle specific industrial conditions, it's less likely to fail under operating conditions. As a result, less operational downtime will occur for repairs and maintenance, allowing for uninterrupted business operations and saving additional costs.

Specific Material Selection: Materials can be chosen to withstand harsh conditions, reducing the need for frequent replacements due to wear, heat, or chemical exposure.

In essence, the customization feature greatly benefits industrial units with limited space without sacrificing efficiency. Regarding the use of pleated filter media, it optimizes energy consumption while ensuring excellent filtering performance. Lastly, customization helps to reduce maintenance costs, mainly by enhancing operational efficiency and reducing the frequency of required repairs or replacements.

Customization Benefits for Limited Space Industries:

The customization feature in the Single-Machine Pulse Jet Bag Dust Collector is a boon for industries where space is a constraint. Here's how:

Spatial Efficiency: The dust collector's size and shape can be customized according to available space, optimally utilizing the workspace without compromising on dust control measures.

Compact and Effective: Despite being tailored to fit smaller spaces, the dust collector can retain high efficiency due to design integrations like pleated filter bags, offering effective dust collection in a compact size.

Flexibility: Not just the size, even the layout and orientation of the unit can be adjusted, making it possible to place the equipment in line with the site's design, maximising space utility.

Energy Efficiency of Pleated Filter Media:

Pleated filter media enhance the energy efficiency of the Single-Machine Pulse Jet Bag Dust Collector in many ways:

Increased Filter Area: The pleated design means more filter area per unit volume. This allows greater dust holding capacity and less frequent cleaning cycles, conserving energy spent on maintaining the cleanliness of the filters.

Reduced Air Pressure Requirement: Thanks to the larger surface area of the pleated filters, less air pressure is required for cleaning, which further reduces energy consumption.

Enhanced Airflow: Pleated filter media improve overall airflow through the system, reducing the work and consequent energy expenditure of the fan installed in the system.

Reducing Maintenance Costs through Customization:

Customization goes a long way in bringing down maintenance costs for businesses:

Longer Lifespan: A dust collector configured to match specific industrial needs will operate under optimal conditions, preventing unnecessary strain on the system, and hence prolonging its life.

Specific Filter Type: Businesses can opt for filters that are crafted to handle the exact particle size and type they deal with, which not only enhances filtration efficiency but also extends filter life, reducing costs associated with filter changes.

Resilience to Operating Conditions: A system that’s tailored to suit the operating conditions of a specific industry will be more robust and less likely to fail, reducing repair or replacement costs.

Material Selection: By selecting materials that can withstand the rigors of a specific environment whether it be heat, chemicals, or abrasive dust, the frequency of maintenance can be minimized, thus saving on costs.

The way pleated filter media are designed in the Single-Machine Pulse Jet Bag Dust Collector can considerably contribute to energy savings:

Improved Airflow: Pleated filter media have a larger surface area compared to traditional bag filters, which allows for improved airflow. This enhanced airflow reduces the energy required to push air through the filter, leading to substantial energy savings.

2.Fewer Cleaning Cycles: Pleated filters can hold more dust before reaching their maximum differential pressure, which means the cleaning cycles are less frequent. As a result, the pulse-jet system uses less compressed air, leading to additional energy savings.

Lower Fan Energy Consumption: As the pleated media provides more efficient airflow, the fan or blower doesn't have to work as hard to maintain adequate air volume, contributing to lower energy consumption.

Maintenance Cost Reductions through Customization:

Customizing the Single-Machine Pulse Jet Bag Dust Collector can help achieve specific reductions in maintenance costs in several ways:

Dust Particle Specific Customization: Filters can be customized to handle the specific type and size of dust particles which the industry produces. If the filters are better suited to tackle the specific dust, they can effectively last longer, reducing the frequency of replacement and maintenance.

Adaptability to Industry Specific Conditions: Tailoring the dust collector to cater to specific industrial needs, such as high temperatures or corrosive environments, can minimize the risk of premature equipment failure or regular need for upkeep, saving on maintenance costs.

Reduced Downtime: A customized dust collector is designed to perform optimally under the unique conditions of your operation. This reduces unnecessary strain on the system and, in turn, reduces downtime for repairs and maintenance, supporting smoother, more cost-effective operations.

Fewer System Replacements: Customized dust collectors are designed to be resilient and withstand the conditions of your industrial environment, which extends the overall lifecycle of the system. This reduces the need for full system replacements and associated costs.

Efficient Filter Cleaning: Customization can optimize the cleaning system to work more effectively with the filter media and dust type. This can extend filter life, decrease differential pressure, and cut energy costs.

By integrating pleated filter media and customization, the Single-Machine Pulse Jet Bag Dust Collector offers an optimized, energy-efficient, and cost-effective solution for dust collection across a wide range of industries.