In the industrial world, maintaining a clean, dust-free environment is crucial. Balancing this need while taking into consideration space constraints, energy consumption, and cost-effectiveness presents a significant challenge. A solution that is capturing attention due to its reliability, efficiency, and customizable nature is the Low Pressure Jet Pulse Bag Filter.

Unveiling the Low Pressure Jet Pulse Bag Filter

The Low Pressure Jet Pulse Bag Filter, as the name suggests, operates on a low pressure mechanism. Unlike other dust collectors that require high pressure to function effectively, this filter does its job at a modest pressure of 0.25 to 0.35MPa. The importance of this low-pressure operation cannot be overstated, as it greatly reduces energy consumption and subsequently improves the lifespan of the filter bag.

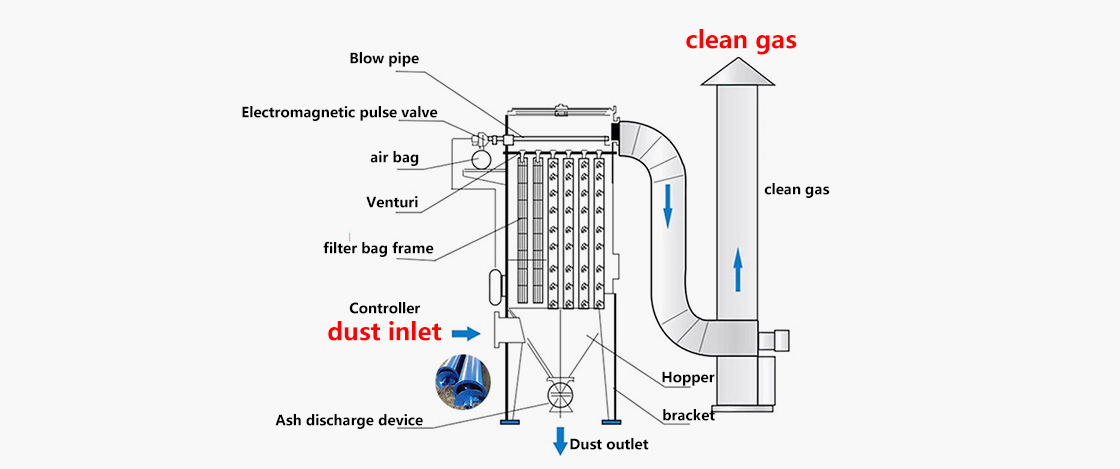

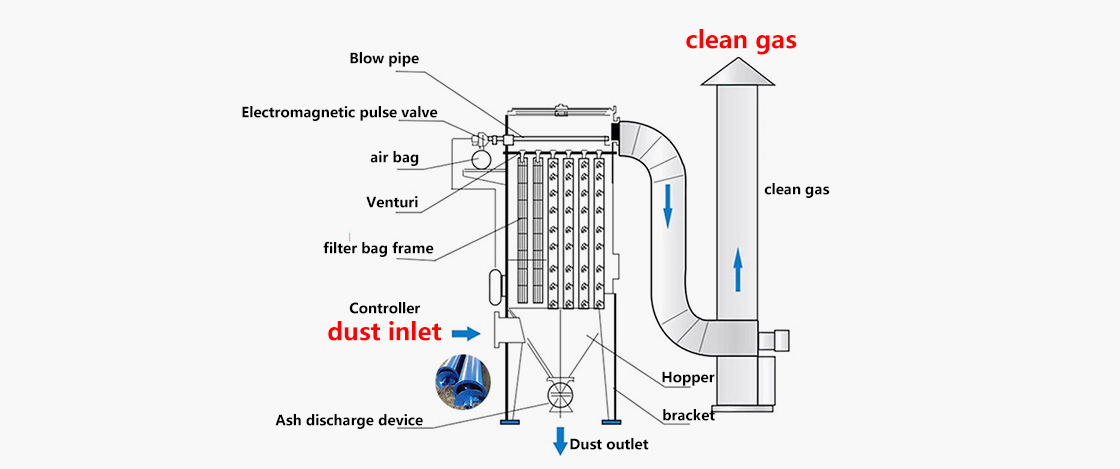

The dust collector is a versatile unit composed of brackets, ash hoppers, filter chambers, clean air chambers, filter bags, injection devices, and controllers. Its brilliance lies in its combination design. It is modular, consisting of 1, 2, 3, and 4 unit specifications, each housing 24 rows of 12 filter bags, each 6 meters long with a diameter of 130mm. With 336 filter bags, the filter area expands to an impressive 800㎡, providing a vast surface for capturing and holding dust.

The Magic of Pleated Filter Bags

The filter bags made from polyester needle-punched felt are lightweight yet durable and capable of handling different types of dusty environments. The pleated design significantly increases the surface area of the filter, allowing more dust to be retained. Combined with the jet pulse cleaning technology, the filter bags scrub off dust thoroughly while conserving compressed air.

Role in Energy-saving and Efficiency

The Low Pressure Jet Pulse Bag Filter adopts a smart control method, adjusting the pulse interval of the injection system based on the resistance of the dust collector. This responsive control minimizes the number of injections, subsequently reducing power consumption, while extending the service life of filter bags, diaphragms, and solenoid valves.

Customization: A Key Advantage

Another major advantage of the Low Pressure Jet Pulse Bag Filter is the flexibility it offers. It can be tailored to your specific needs, fitting into the kind of space available while ensuring stable and reliable performance. This customization not only ensures a perfect fit for your workspace but also reduces maintenance costs in the long run.

Cost-effective, Compact and Lightweight

True to the saying 'big things come in small packages,' this dust collector is compact and lightweight, occupying minimal space while delivering maximal efficiency. It's about 1/3 the weight and land cost of a large-scale back-blowing bag filter with the same processing air volume.

Application Scope

Low Pressure Jet Pulse Bag Filters are highly sought after in a variety of industrial sectors. They're ideal for use in metallurgy, foundries, mining, chemical industry, cement building materials, and other sectors dealing with air particles, smoke pollution, and ultra-fine dust air. Whether you're dealing with a small production unit or a large industrial operation, these filters adjust up and down scale with relative ease, accommodating diverse requirements.

In a world where businesses are increasingly focusing on efficiency, cost-effectiveness, and environmentally friendly initiatives, the Low Pressure Jet Pulse Bag Filter is an absolute game-changer. With its unique combination of energy saving, reliable performance, reduced maintenance costs, and customizable design, it's carving a niche for itself in dust management, offering businesses a smart, efficient, and flexible solution for their dust control needs.

The Low Pressure Jet Pulse Bag Filter (LPJPBF) is a tale of how small changes can lead to significant impacts. Its brilliant design capitalizes on low-pressure operation and dynamic control methods to impeach high energy costs, transforming it into a beacon of efficiency and energy savings.

Low-Pressure Operation: Unlike conventional dust filters that operate under high pressure, the LPJPBF functions within a lower pressure range, typically between 0.25–0.35MPa. Lower pressure translates into lesser energy being expended to maintain the system's operations, contributing to noticeable energy savings.

Efficient Dust Cleaning: LPJPBF uses a pulse injection system for cleaning the filter bags. Since this system operates on low pressure, it requires less electricity to generate the pulse power. This efficient cleaning combined with lower energy requirements significantly reduces overall energy usage.

Dynamic Pulse Interval Management: Another feature of LPJPBF is its dynamic pulse control. The system adjusts the pulse interval based on the resistance faced by the dust collector. When the resistance rises, the pulse interval shortens, leading to fast injection and vice versa. This intelligent method not only maintains optimal dust filtration but also minimizes the number of injections, saving energy in the process.

Reduced Load on Other Components: By operating at low pressure, LPJPBF eases the strain on other components such as diaphragms, solenoid valves, and the power motor. This reduced wear and tear result in fewer breakdowns and less energy wasted on excessive operational intensity.

Prolonged Filter Lifespan: The low-pressure operation prolongs the lifespan of the filter bags. The longer the bags last, the fewer resources and energy are required for replacing them, indirectly contributing to energy conservation.

In essence, the Low Pressure Jet Pulse Bag Filter has been winning laurels in the industrial sector because of its ingenious method of linking low pressure with high efficiency, demonstrating that energy effectiveness doesn't always necessitate high power. Its success story provides compelling evidence that energy savings and eco-friendly practices can go hand-in-hand with outstanding performance and reliability.

The dynamic pulse interval management in the Low Pressure Jet Pulse Bag Filter (LPJPBF) is one of the key factors contributing to the energy efficiency of the system. It does so through the following ways:

Adaptive Pulse Frequency: The primary feature of dynamic pulse interval management is its ability to adapt the frequency of filter cleaning pulses based on real-time needs. The pulse interval is shortened when resistance increases, leading to fast, frequent injection (cleaning). Conversely, when resistance decreases, the pulse interval is lengthened, resulting in slower, less frequent injection. By constantly adapting the pulse frequency to current conditions, energy wastage from unnecessary, excessively frequent pulses is reduced.

Optimized Compressed Air Use: The entire process is driven by compressed air, which accounts for a major chunk of energy consumption in a pulse jet bag filter system. With dynamic pulse interval management, the use of compressed air is optimized based on the actual need for cleaning. This approach ensures that the consumption of compressed air, and hence, energy, is optimized and not wasted on needless cleaning cycles.

Extended Component Life: Adaptive pulse frequency minimizes the number of injections, reducing wear and tear on parts like filter bags, diaphragms, and solenoid valves. This translates to fewer replacements and repairs, further contributing to energy savings in manufacturing and installing new components.

Balanced System Performance: The dynamic pulse interval management helps to balance the resistance, air volume, and compressed air consumption of the LPJPBF. By maintaining a stable operating environment, it ensures that the system runs efficiently, avoiding energy wastage due to system instability.

In essence, the dynamic pulse interval management system of the LPJPBF demonstrates a commendable merger of innovative design and energy efficiency. By intelligently assessing and altering cleaning cycles, this feature encapsulates a greener footprint, reduced operating costs, and a longer product lifespan - reflecting a future-forward approach to the age-old issue of industrial dust collection.

The dynamic pulse interval management in the Low Pressure Jet Pulse Bag Filter (LPJPBF) is one of the key factors contributing to the energy efficiency of the system. It does so through the following ways:

Adaptive Pulse Frequency: The primary feature of dynamic pulse interval management is its ability to adapt the frequency of filter cleaning pulses based on real-time needs. The pulse interval is shortened when resistance increases, leading to fast, frequent injection (cleaning). Conversely, when resistance decreases, the pulse interval is lengthened, resulting in slower, less frequent injection. By constantly adapting the pulse frequency to current conditions, energy wastage from unnecessary, excessively frequent pulses is reduced.

Optimized Compressed Air Use: The entire process is driven by compressed air, which accounts for a major chunk of energy consumption in a pulse jet bag filter system. With dynamic pulse interval management, the use of compressed air is optimized based on the actual need for cleaning. This approach ensures that the consumption of compressed air, and hence, energy, is optimized and not wasted on needless cleaning cycles.

Extended Component Life: Adaptive pulse frequency minimizes the number of injections, reducing wear and tear on parts like filter bags, diaphragms, and solenoid valves. This translates to fewer replacements and repairs, further contributing to energy savings in manufacturing and installing new components.

Balanced System Performance: The dynamic pulse interval management helps to balance the resistance, air volume, and compressed air consumption of the LPJPBF. By maintaining a stable operating environment, it ensures that the system runs efficiently, avoiding energy wastage due to system instability.

In essence, the dynamic pulse interval management system of the LPJPBF demonstrates a commendable merger of innovative design and energy efficiency. By intelligently assessing and altering cleaning cycles, this feature encapsulates a greener footprint, reduced operating costs, and a longer product lifespan - reflecting a future-forward approach to the age-old issue of industrial dust collection.

The dynamic pulse interval management system significantly contributes to reducing power consumption in the Low Pressure Jet Pulse Bag Filter (LPJPBF) due to several factors.

Adaptive Pulse Frequencies: In the LPJPBF, compressed air is used to clean the filter bags by generating pulse injections. Higher pulse frequency would mean greater use of compressed air, which in turn would require more power to generate this compressed air. The dynamic pulse interval management system smartly adapts the frequency of pulses in accordance with real-time resistance faced by the dust collector. As a result, during periods when the resistance is lower, the pulse frequency decreases, thereby reducing the power needed for compressed air generation.

Optimisation of Compressed Air Use: Converting ambient air into compressed air consumes a significant amount of energy. The dynamic pulse interval management system optimizes the use of compressed air by varying the pulse frequency based on the need for filter cleaning. Lower pulse frequency equates to less compressed air being used, thereby reducing the energy requirements.

Reduced Component Stress: Frequent pulse injections put increased stress on components like diaphragms and solenoid valves, leading to higher power consumption. By decreasing the pulse frequency when it's feasible, the dynamic pulse interval management system can protect these components from excessive stress, thereby minimising power usage.

Prevention of Unnecessary Energy Use: Traditional pulse bag filter systems operate on a fixed pulse frequency, which often leads to situations where energy is used to generate pulses that aren't needed. The dynamic pulse interval management system prevents this unnecessary energy use, thus saving power.

In conclusion, by intelligently managing the pulse frequency, the dynamic pulse interval management system goes a long way in reducing power consumption of the LPJPBF, making it an eco-friendly and economical choice.

The dynamic pulse interval management system significantly contributes to reducing power consumption in the Low Pressure Jet Pulse Bag Filter (LPJPBF) due to several factors.

Adaptive Pulse Frequencies: In the LPJPBF, compressed air is used to clean the filter bags by generating pulse injections. Higher pulse frequency would mean greater use of compressed air, which in turn would require more power to generate this compressed air. The dynamic pulse interval management system smartly adapts the frequency of pulses in accordance with real-time resistance faced by the dust collector. As a result, during periods when the resistance is lower, the pulse frequency decreases, thereby reducing the power needed for compressed air generation.

Optimisation of Compressed Air Use: Converting ambient air into compressed air consumes a significant amount of energy. The dynamic pulse interval management system optimizes the use of compressed air by varying the pulse frequency based on the need for filter cleaning. Lower pulse frequency equates to less compressed air being used, thereby reducing the energy requirements.

Reduced Component Stress: Frequent pulse injections put increased stress on components like diaphragms and solenoid valves, leading to higher power consumption. By decreasing the pulse frequency when it's feasible, the dynamic pulse interval management system can protect these components from excessive stress, thereby minimising power usage.

Prevention of Unnecessary Energy Use: Traditional pulse bag filter systems operate on a fixed pulse frequency, which often leads to situations where energy is used to generate pulses that aren't needed. The dynamic pulse interval management system prevents this unnecessary energy use, thus saving power.

In conclusion, by intelligently managing the pulse frequency, the dynamic pulse interval management system goes a long way in reducing power consumption of the LPJPBF, making it an eco-friendly and economical choice.

The dynamic pulse interval management system helps maintain balance in the Low Pressure Jet Pulse Bag Filter (LPJPBF) in multiple ways.

Balanced Cleaning: One of the main functions of the dynamic pulse interval management system is to adjust the frequency of the cleaning pulses according to the current load and dust accumulation levels. Rather than firing pulses at a fixed interval, which can cause certain areas to be over-cleaned while others are under-cleaned, this system ensures a balanced cleaning of all areas based on need.

Preservation of System Efficiency: By adjusting pulse intervals to match real-time conditions, the system ensures that pressure drop across the filter bags remains within optimal limits. This avoids undue stress on any specific area of the system, and maintains the overall balance and efficiency of the LPJPBF.

Protection of Components: LPJPBF components such as diaphragms, solenoid valves and filter bags can be stressed if they are subjected to pulses with high frequency. The dynamic pulse interval management system adjusts the frequency of pulses to achieve an even load on the components, thereby protecting them from undue stress and wear, ensuring they last longer and work more efficiently.

Conserving Resources: The system dynamically adapts to variations in operation conditions, ensuring optimal usage of resources like compressed air and power. This ensures that no part of the system is over- or under-utilized, thereby maintaining an overall balance in the system's resource consumption and avoiding wasteful uses of resources.

Maintenance Balance: With a dynamic pulse interval management system, the maintenance of the LPJPBF is more controlled and predictable. There will be less premature replacements of filter bags or other components because of the balanced use.

In summary, the dynamic pulse interval management system ensures more efficient operation, better use of resources, and a longer life for system components, all of which contribute to maintaining a balance in the operation of the LPJPBF.

The dynamic pulse interval management system optimizes the cleaning process of the Low Pressure Jet Pulse Bag Filter (LPJPBF) in several ways:

Adaptive Cleaning Frequency: Instead of releasing cleaning pulses at set intervals, the dynamic pulse interval management system adapts the pulse frequency based on the real-time dust load on the filter bags. This means cleaning pulses are fired when necessary, resulting in more effective cleaning and less wear on the filter bags.

Avoid Over-Cleaning and Under-Cleaning: With a dynamic pulse interval management system, cleaning pulses are fired only when needed. This prevents over-cleaning (which can unnecessarily wear out the filter bags) and under-cleaning (which can lead to dust buildup and decreased filter efficiency).

Optimal Use of Compressed Air: Conventional pulse jet cleaning systems use a significant amount of compressed air, regardless of the actual cleaning needs. The dynamic pulse interval management system can regulate the volume and frequency of each pulse, ensuring that just the right amount of air is used for cleaning, which saves resources and contributes to overall system efficiency.

Extended Filter Life: Regular and appropriate cleaning maintains the permeability of the filter bags, ensuring a lower pressure drop and extending their service life. A longer filter lifespan leads to reduced maintenance costs and less operational downtime.

Real-Time Decision Making: The system continuously monitors operational parameters that can influence the cleaning requirements, such as air flow, pressure drop across the filter, and dust load. Based on these parameters, it makes real-time decisions regarding the timing and frequency of the cleaning pulses, optimizing the cleaning process to match the current operating conditions.

Through these mechanisms, the dynamic pulse interval management system enhances the efficiency and effectiveness of the LPJPBF cleaning process, ensuring optimal performance.

The dynamic pulse interval management system continually monitors various operational parameters to make real-time cleaning decisions in the Low Pressure Jet Pulse Bag Filter (LPJPBF). These parameters include:

Differential Pressure: The system monitors the pressure drop across the filter bags, which is indicative of dust accumulation. Increased pressure drop suggests more dust build-up and vice-versa. Based on this, the system adjusts the pulse frequency.

Airflow Rate: By measuring the flow rate of the air passing through the filter bags, the system can infer the dust-loading condition. Lower than normal airflow can suggest a high dust load and the need for more frequent cleaning pulses.

Time: The system takes into consideration the operational time elapsed since the last cleaning. Depending on the nature of the dust and the ambient conditions, dust can adhere more firmly to the bags over time. So, regular cleaning within specific time intervals is crucial.

Dust Load: Some systems have sensors to measure the quantity and properties of the dust in the air before it enters the LPJPBF. By understanding the dust load in real-time, the system can adjust the cleaning pulse frequency proactively.

Ambient Conditions: Parameters such as temperature and humidity also play a role in dust adhesion to the bags and thus are considered in determining the cleaning intervals and frequency.

By monitoring these parameters, the dynamic pulse interval management system can adapt the cleaning frequency to match the current operating conditions, optimizing the operation of the LPJPBF and ensuring the filter bags are cleaned effectively when necessary. It greatly enhances the efficiency, longevity, and reliability of the entire system.