Introduction

In the real world of manufacturing, dust is far more than just a housekeeping issue. It can present significant safety hazards and serious health risks, hinder operational efficiency, and create regulatory compliance issues. The innovative Long Bag Offline Pulse Dust Collector is a cutting-edge solution that addresses all these dust-related challenges with unparalleled efficiency and reliability. This review aims to explore the remarkable features and advantages of this advanced dust collector, aspiring to engage discussion within the industry.

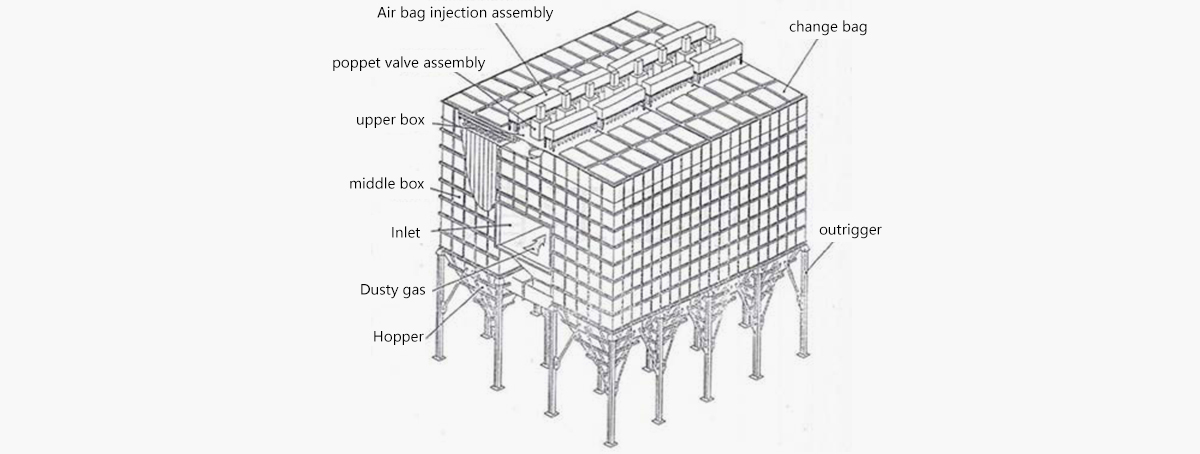

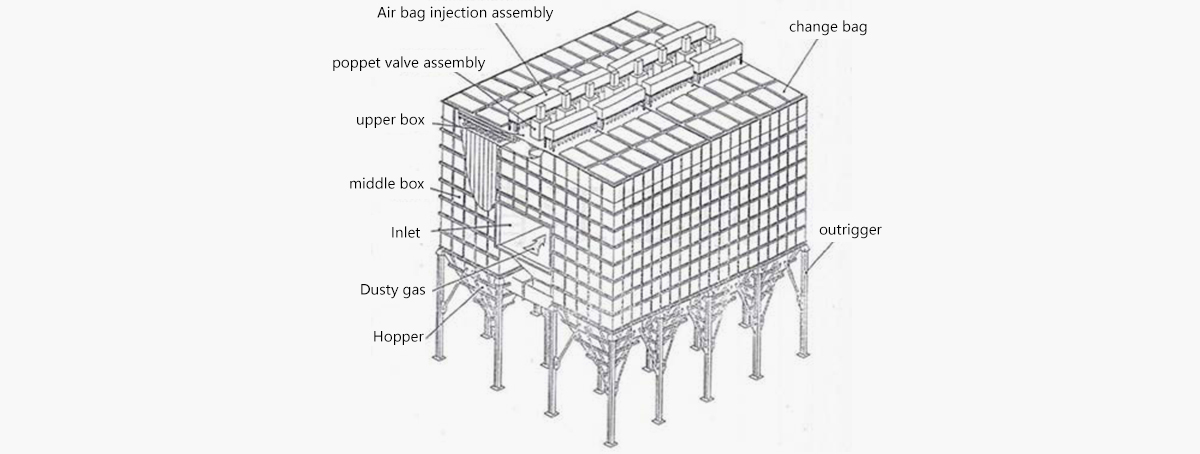

Core Features of The Long Bag Offline Pulse Dust Collector

At the heart of the Long Bag Offline Pulse Dust Collector is its unique and meticulously engineered long-bag pulse system. Setting itself apart from conventional short-bag pulse dust collectors, this new type of dust collector not only integrates the benefits of sub-chamber backflushing and pulse jet cleaning, but also lengthens the filter bag to fully utilize the powerful jet cleaning of compressed air.

Cleaning Efficiency and Energy Consumption

With its breakthrough bag-foot design, the innovative pulse dust collector effectively overcomes the shortcomings of low intensity backflushing in separate chambers. By ingeniously utilizing simultaneous pulse jet cleaning and dust filtration, the device prevents the issue of dust reattachment and loss of control. Consequently, the filtration speed is enhanced, energy consumption for cleaning is significantly reduced, and the lifespan of the filter bag is remarkably prolonged.

Versatile Applications

The strength of the Long Bag Offline Pulse Dust Collector lies not just in its advanced technical design but also in its adaptability to a wide assortment of industries. Whether it's a mechanical equipment workshop, grinding power plant, steel plant, cement plant, or carbon foundry, this dust collector exhibits a fantastic performance. It effectively filters airborne particles, smoke pollution, and ultra-fine dust air, ensuring a clean and safe working environment across multiple industrial sectors.

Structural Integrity and Operational Stability

The integrity of the Long Bag Dust Collector is underpinned by its thickened sheet structure that guarantees robust and reliable operation. The device features an elastic expansion ring at the mouth of the filter bag, which endows it with excellent sealing performance that is both firm and dependable. Additionally, unlike conventional designs, the maintenance and replacement of the bags can be performed under the normal operating conditions of the system, making it unnecessary to stop the system fan.

Optimized Efficiency, Longevity, and Convenience

This new generation dust collector offers numerous efficiency enhancements, such as compactly arranged inlet and outlet air ducts, which minimize airflow resistance. The filter bag keel is designed in a polygonal shape to reduce friction between the bag and keel, significantly extending the filter bag's life. Moreover, the system's dust collectors can be selected based on various factors such as dust concentration and different filter materials, offering unmatched convenience to users.

Air-tight Design

Another impressive aspect of the Long Bag Offline Pulse Dust Collector is its air-tight design. With formidable sealing performance, excellent inspection sealing material, and effective oil leak detection, the device maintains a low air leakage rate, redefining the standard in dust collecting technology.

Conclusion

In conclusion, the Long Bag Offline Pulse Dust Collector signifies a pivotal advancement in dust collection technology. With its blend of innovative features, the device provides a powerful weapon in the battle against dust-related issues in multiple industrial sectors. Its versatile adaptability, structural integrity, optimized efficiency, and meticulous attention to detail place it as a market leader, setting a benchmark for future designs in the field. The Long Bag Offline Pulse Dust Collector is more than just a tool—it is a game-changer, ready to revolutionize the way we perceive and handle industrial dust.

The Long Bag Offline Pulse Dust Collector offers several key advancements over traditional short-bag pulse dust collectors. Firstly, the most significant difference is the length of the bag used for filtration. The longer bag allows for more surface area for dust particles to adhere to, thereby increasing the efficiency of dust removal. Secondly, innovative technology merges the benefits of the sub-chamber backflushing and pulse jet cleaning methods, while also resolving their individual weaknesses. This includes the low intensity of separate chamber backflushing and the reattachment of dust particles during simultaneous pulse jet cleaning.

Industries that can largely profit from employing the Long Bag Offline Pulse Dust Collector include the mechanical equipment workshop, grinding power plant, steel plant, cement plant, and carbon foundry. These sectors often deal with particles, smoke pollution, and ultra-fine dust air, making the Long Bag Offline Pulse Dust Collector's advanced filtering capabilities particularly beneficial.

Key features that contribute to the Long Bag Offline Pulse Dust Collector's efficiency and reliability include:

Powerful Jet Cleaning: The unit utilizes the force of compressed air to create a strong jet stream that effectively removes dust particles.

Long Filter Bag: A longer bag extends the filter's lifespan and increases the filtration speed, enhancing the unit's overall efficiency.

Advanced PLC Programmable Controller: This controller automates the control of the exhaust valve, pulse valve, and ash discharge valve, reducing manual intervention and improving reliability.

Low Energy Consumption: The system's design reduces the energy required for cleaning, resulting in cost savings.

Structural Robustness: The unit's structure, featuring a thickened sheet and elastic expansion ring at the filter bag mouth, ensures reliable sealing performance and system stability.

Adaptability: The dust collector can be customized according to different industry's requirements, including dust concentration and filter material selection.

All these elements, when combined, make the Long Bag Offline Pulse Dust

The jet cleaning system in the Long Bag Offline Pulse Dust Collector enables efficient dust removal, contributing significantly to the overall efficiency of the unit. This system utilizes compressed air to create a powerful jet stream, which is directed at the filter bag. As this forceful air stream hits the bag, it causes a rapid flexing that dislodges dust particles from the bag's surface without damaging the bag itself. This in-depth cleaning process restores the filter's permeability and optimizes filtration effectiveness, ensuring a high level of dust collection efficiency is maintained over time.

The advanced PLC (Programmable Logic Controller) plays a critical role in automating the operation of the Long Bag Offline Pulse Dust Collector. It intelligently manages the functions of the exhaust valve, pulse valve, and ash discharge valve, synchronizing their activities based on real-time conditions within the system. This automation eliminates potential human error, enhances the reliability of the system, maintains optimal dust collection efficiency, and ultimately prolongs the life of the filter bag. The PLC also can be programmed to activate cleaning cycles at specific intervals or in response to specific triggers (such as a high differential pressure across the filter bag), ensuring the system operates at maximum efficiency at all times.

The jet cleaning system of the Long Bag Offline Pulse Dust Collector relies on the powerful action of compressed air. However, the efficacy lies not just in the force, but also in the manner in which this force is applied.

The system operates by directing a brief, high-speed burst of compressed air into the inside of the filter bag. This sudden and potent rush of air creates a controlled 'shock wave' that travels along the length of the filter bag. As a result, dust particles accumulated on the outside of the bag are swiftly and efficiently dislodged.

Importantly, the process does not necessitate any physical contact with the filter bag, and the quick, gentle flexing action of the shock wave prevents any undue strain or wear on the bag. So, despite the high intensity of the cleaning pulse, the process is incredibly gentle on the bag material, ensuring its longevity. This effective yet careful cleaning process is one of the central innovations of the Long Bag Offline Pulse Dust Collector, setting it apart from traditional dust control solutions.

The Long Bag Offline Pulse Dust Collector ensures that the filter bag material is not strained or damaged during the cleaning process through the use of two key mechanisms - the design of the jet pulse and the strength of the filter bags.

Design of the Jet Pulse: The cleaning process relies on a quick, high-intensity burst of air, instead of a sustained, high-pressure flow. This 'pulse' is powerful enough to dislodge dust particles from the filter bag, but the force is concentrated within a short period of time, reducing the overall stress on the bag material. The "shock wave" effect created is powerful enough to shake off the dust, but it's not strong enough to induce adverse strain on the bag.

Strength and Quality of the Filter Bags: The filter bags in Long Bag Offline Pulse Dust Collectors are typically made from strong, industrial-grade fabric materials such as polyester, polypropylene, or nomex. These fabrics are designed to withstand not just the high-volume airflow inside the collector, but also the stress of regular cleaning pulses. Some designs include reinforcing or protective features, such as over-cages, to further protect the bags from forceful bursts of air during the cleaning process.

Through these measures, the Long Bag Offline Pulse Dust Collector ensures a thorough yet careful cleaning of the filter bags, extending their lifespan and maintaining the efficiency of the dust collector system.

The filter bags in the Long Bag Offline Pulse Dust Collector are typically manufactured from a few types of fabric materials, each chosen for its unique properties that counter the harsh conditions inside the dust collector. Here are some common fabric materials:

Polyester: This is widely favored due to its high strength, resistance to most mineral acids, and good resistance to weathering and abrasion.

Polypropylene: It is often chosen for its excellent resistance to most acids and alkalis. It also boasts a lower density than other fibers, potentially providing savings in terms of energy and cost, and it has significant moisture resistance.

Nomex (Aramid): This material is appreciated for its high temperature resistance, which makes it suitable for dust collectors operating in high-temperature environments.

PTFE (Teflon): The PTFE filters are used in situations where the dust collector is exposed to chemicals or moisture. They provide excellent resistance to a wide range of chemicals, coupled with the ability to withstand high temperature.

Fiberglass: Fiberglass is a good material for applications where high temperatures are an issue. It maintains high strength and good resistance to abrasion, though it's not recommended for high acid and alkali applications.

Acrylic: Acrylic offers good resistance to organic solvents, oxidizing agents, inorganic and organic acids. It also maintains moderate strength when wet or dry.

Each fabric's suitability ultimately depends on the specific application's conditions, like the type of dust, the operating temperature, and the collector's physical layout. That's why it's important to pick the right filter bag material to achieve optimal performance in a Long Bag Offline Pulse Dust Collector.

PTFE, often known as Teflon, provides two main advantages when used as the fabric material for filter bags in a Long Bag Offline Pulse Dust Collector: superior chemical resistance and excellent temperature tolerance.

Chemical Resistance: PTFE is a material that's very resistant to various types of chemicals. This resistance extends to both acidic and basic compounds, allowing it to work effectively in environments with a wide pH range. This makes PTFE filter bags highly beneficial in industries where the dust or air stream might contain strong chemicals, noxious gases, or other corrosive elements.

Temperature Tolerance: PTFE filter bags show excellent resistance to high temperatures. They can withstand intense heat while maintaining their structure and integrity, which is especially beneficial for high-temperature applications. In many cases, PTFE filter bags are capable of continuous operation at temperatures up to 260 degrees Celsius (500 degrees Fahrenheit), and they can also handle peak temperatures that are even higher.

Because of these advantages, PTFE filter bags are commonly used in situations involving high temperatures and harsh chemical conditions, such as incinerator systems, chemical processing plants and operations involving the generation of hazardous waste. When exposed to such severe conditions, the PTFE filter bag ensures the Long Bag Offline Pulse Dust Collector can maintain highly efficient and consistent dust filtration.