Introduction

Clean, clear, and healthy water is a vital necessity in every aspect of life. Whether for drinking, showers, laundry, gardening, or industrial purposes, the quality of water greatly affects our health, daily tasks, and overall life quality. Disappointingly, finding clean water free from impurities and harmful substances is becoming increasingly difficult. Hence, companies like Lefilter are developing innovative solutions like the Automatic Backwash Filters to address this challenge.

Main Components and Their Key Functions

At the heart of Lefilter’s Backwash Filters are its main components - a cartridge, a stainless steel screen, an electric drainage valve and a drainage device. The stainless steel screen plays a key role in filtering out impurities, ensuring only clean water flows out of the system. The electric drainage valve and drainage device facilitate the disposal of intercepted impurities when required.

Automatic Backwash System

The real magic of Lefilter’s Backwash Filters lies in its Automatic Backwash System. The system is designed with modularity in mind, adopting a forward filtration and reverse backwashing approach. This ingenious design allows for large filtration area, high dirt holding capacity, and automatic backwashing function, even amidst fluctuating water quality conditions.

Key Applications

Lefilter’s Automatic Backwash Filters are perfect for a wide range of applications, e.g. heating systems for hot water circulation, cooling and chilling water circulation systems for air conditioners, chillers and refrigerators, industrial and civil cooling water, and circulation systems for bathing and heating using geothermal water. Their versatile design ensures reliable and efficient performance in various environmental conditions.

Filtration Media

The primary role of the filtration media is to remove various sticky substances, gum particles, silt and other mechanical impurities from water. This results in clean, clear, and odor-free water, ideal for a myriad of applications.

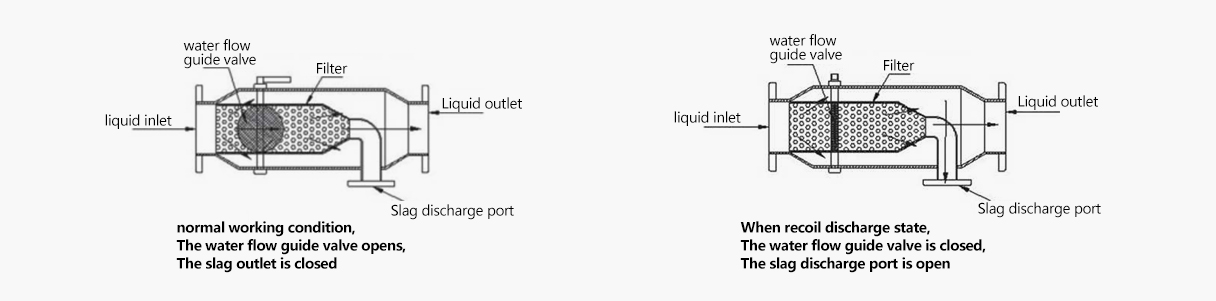

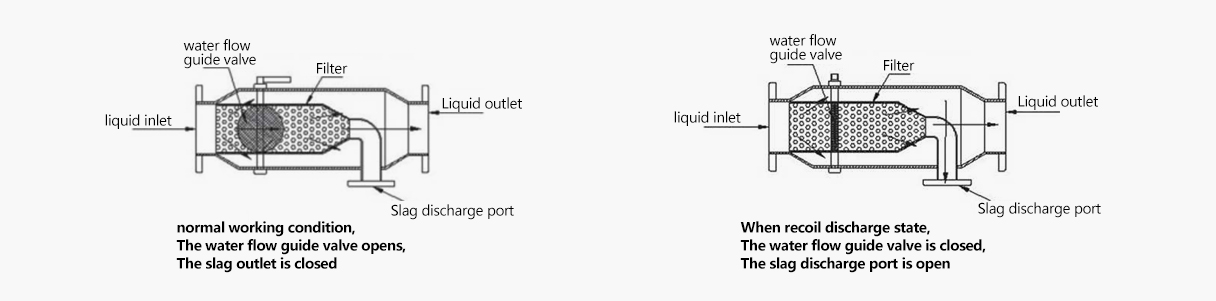

Working Principle

In normal operation, the backwash filter allows water to be filtered through the filter cartridge and discharged through the outlet. During the backwash cycle, dirty water enters from within the filter cartridge outwards, forcing stuck impurities to be washed away and ultimately ensuring that clean, filtered water is produced consistently.

Advantages of Lefilter's Backwash Filters

Automation Control System: The intelligent control system is responsive, accurate, and easy to operate.

High-Performance Precision Filter Element: The V-shaped gap precision filter element effectively filters pollutants and impurities that are typically hard to backwash like microfiltration residue, sludge, and soft agglomerations.

Overall Structure Advantages: The equipment requires no consumables and has fewer wearing parts, leading to lower operating costs.

Conclusion

Lefilters' innovative backwash filters are an epitome of modern filtration technology culmination. By integrating advanced features like automatic backwash systems, precision filter elements, and intelligent control systems, these filters represent a significant step forward in water filtration technology. Whether for residential or industrial applications, Lefilter's backwash filters promise optimum water quality, operational efficiency, and cost-effectiveness, meeting and surpassing customers' expectations with ease.

Remember, with Lefilter, you are not just purchasing a product, but investing in a lifetime solution for all your water filtration needs.

To experience the transformative power of our Backwash Filters, reach out to our team today. Let's work together to ensure your water is of the absolute best quality, and your life, as a result, significantly enhanced.

Lefilter's Automatic Backwash System is designed with an innovative module that utilizes forward filtration and reverse backwashing. This module is capable of handling unstable water quality fluctuations, thus ensuring efficient filtration in all circumstances. Here's how it does this:

Large Filtration Area: The multi-core structure of the backwash system provides a larger filtration surface area. This large surface area increases the system's capacity to trap and eliminate a broader range of impurities from the water, even when water quality is erratic.

Increased Dirt Holding Capacity: With a large filtration area, Lefilter's Backwash Filters also have a high dirt holding capacity, meaning they can trap and hold a significant amount of impurities without the need for frequent backwashing. This feature is particularly beneficial when the filter is faced with water of inconsistent quality, containing high amounts of impurities.

Adaptive Backwashing Function: The automatic backwashing function works adaptively according to the quality of incoming water. When the amount of trapped impurities reaches a certain level—typically when water quality is poor—, the backwash starts automatically, cleaning the filter and restoring filtration efficiency. This means the system constantly reacts and adjusts to the water quality fluctuations, ensuring its filtration efficiency.

Efficient Filtration Media: Lefilter's Automatic Backwash Filters utilize high-performance precision filter elements that are capable of capturing a wide range of impurities, from sticky substances to silt and other mechanical impurities. Their efficiency remains high, even when faced with variable water quality.

Intelligent Control System: The intelligent control system monitors the filtration process closely and adjusts the filtration and backwashing frequency according to the real-time water quality. It responds quickly and accurately to changes in water quality, helping to maintain consistent filtration performance.

Therefore, regardless of the water quality variations, Lefilter's Automatic Backwash System ensures constant high filtration efficiency, providing clean and safe water under all circumstances.

The adaptive backwashing function in Lefilter's Automatic Backwash System is a crucial component that guarantees efficient filtration and the longevity of the system. The function works based on timing and pressure differential conditions or a combination of both. Here are the steps that elaborate on how this feature works:

Monitoring Filtration Process: The system continually tracks the filtration process. An included pressure gauge or sensor recognizes the difference in pressure between the inlet and outlet of the filter. As the filter screen accumulates debris and impurities over time, the pressure difference rises.

Reaching Threshold: The system is programmed to trigger backwashing once this pressure difference reaches a preset threshold, typically between 5 to 15 PSI or after a set duration. The duration could be in hours, days, or even weeks depending on the water quality and usage.

Initiating Backwashing: Once the conditions are met, the system initiates the backwashing process. The backwashing butterfly valve plate is closed, and the drain valve is opened.

Backwash Cycle: During backwash, water flows in reverse or from the inside out. This reversal of flow, along with the increased velocity, helps dislodge the accumulated impurities from the filter screen.

Expulsion of Waste: This backwashed water carrying the accumulated impurities is then expelled through the drain outlet, ensuring the screen becomes clean and ready for the next round of filtration.

Resetting for Next Round: Post backwashing, the system resets itself for the next filtration cycle, with the butterfly valve plate reopening, and the drain valve closing.

Continuous Operation: Most impressively, during the backwashing cycle, filtration continues in other parts of the system, ensuring uninterrupted filtration and water supply.

In a nutshell, the adaptive backwashing function makes Lefilter's Automatic Backwash System a self-cleaning filter. By constantly monitoring and adapting to the conditions within the filter, this function ensures the filter operates at its optimum efficiency, handling varying water quality expertly, and drastically reducing maintenance needs.

The determination of when to initiate the backwash process in the adaptive backwashing function of Lefilter's Automatic Backwash System is based on either a set time interval or a pressure differential, or a combination of both. Here's how these work:

Time-based Backwashing: In this scenario, the backwashing function is triggered after a predetermined period of operation — say after a specific number of hours, days, or weeks. The filter is programmed to conduct the backwash at regular intervals regardless of the amount of impurities accumulated. This method is typically used in environments where the water quality is generally consistent with predictable levels of impurities.

Pressure Differential Backwashing: In this mode, the backwashing process starts when the pressure difference between the inlet and outlet of the filter reaches a specific threshold. This method is used in environments where the water quality can be quite variable. As the filter accumulates more debris and impurities, the water flow is hampered, leading to an increase in the pressure differential. Once this differential reaches a specific preset threshold (typically around 5 to 15 PSI), the system automatically triggers the backwash process.

Combination Backwashing: Some advanced models can combine both methods. This combined approach ensures that backwashing occurs routinely to maintain the filter's longevity but also automatically triggers when unexpected surges in impurity levels result in a significant pressure differential.

In each case, the aim is to maintain the filter's effectiveness in trapping impurities and ensure a consistent flow of clean, filtered water. The method chosen largely depends on the specific environmental conditions and the kind of impurities typically present in the water. This adaptive nature of Lefilter's Automatic Backwash System ensures efficient filtration while prolonging the life of the filter.

The typical pressure differential threshold that triggers the backwash process in systems like Lefilter's Automatic Backwash System generally falls within the range of 5 to 15 PSI (pounds per square inch). This means that once the difference in pressure between the inlet and outlet of the filter reaches this level, it signals that the filter pores may be getting blocked by accumulated impurities, and the backwash process is automatically initiated.

However, it's important to note that these values can vary depending on the specific filtration system, filter medium, type of impurities, and the water quality. Some systems may have user-adjustable settings to fine-tune this threshold according to the unique requirements of their application.

This threshold is set strategically to ensure optimal filtration efficacy and also prevent any potential damage to the filtration system caused by excessive pressure. By reacting to the pressure differential, the automatic backwashing feature ensures the filter continuously operates at optimal filtration capacity.

The backwash process in Lefilter's Automatic Backwash System plays a crucial role in maintaining the effectiveness of the filtration system and preventing potential damage from excessive pressure. Here's how it achieves this:

Pressure Regulation: Accumulated debris and impurities on the filter screen over time can obstruct water flow, leading to an increase in pressure inside the system. When the pressure differential (the difference in pressure between the inlet and outlet) hits a pre-set threshold (usually 5 to 15 PSI), the backwash process is automatically initiated. This ensures that the pressure never reaches a level that could pose a risk to the system's components, thus preventing damage.

Cleaning of Filter Screen: Backwashing involves reversing the flow of water, which dislodges and flushes away the accumulated impurities from the filter screen. After a successful backwash, the screen should be as good as new, ready for another round of filtration. This self-cleaning process helps to maintain the efficiency of the filtration system.

Uninterrupted Filtration: The brilliant design of the backwash system allows continuous filtration even during the backwash process. In multi-chamber systems, while one chamber is being backwashed, the other chambers continue to filter water. This ensures a consistent water supply and prevents pressure build-up that could occur if the system had to shut down entirely for cleaning.

Increased Lifecycle: By maintaining prime operating conditions within the filter, the automatic backwash process significantly extends the lifespan of the system, reducing the frequency and costs of maintenance and replacement parts.

In summary, through timely and efficient backwashing, the system ensures it operates within safe pressure limits, maintains filtration efficiency, and extends the overall lifespan of the unit.