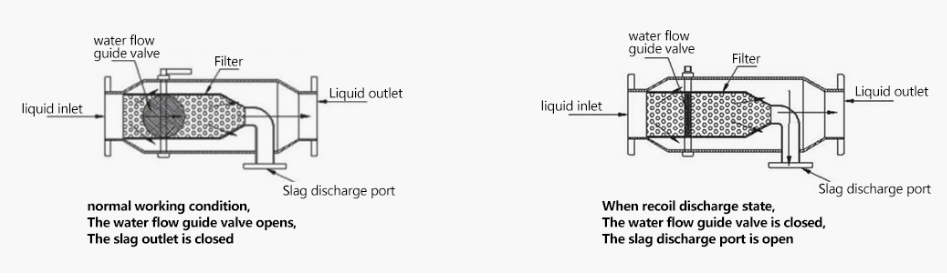

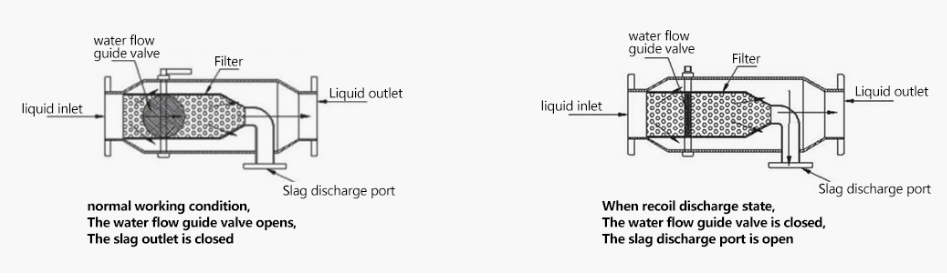

The automatic backwashing filter consists primarily of a cartridge, stainless steel screen, electric drainage valve, and drainage device. During operation, the backwashing butterfly valve plate opens, allowing water to enter the filter cartridge via the inlet. After passing through the cartridge, impurities are trapped inside. When drainage is necessary, the butterfly valve plate closes, and the drain valve opens. Water flows through the outer half of the rear section of the screen, filtering through the first half. Some water exits through the outlet, while the remainder passes through the inner side of the screen's outer half and exits through the drain outlet, facilitating reverse automatic flushing of the screen.

Applications scope

Heating systems for heating, hot water circulation systems for heating; cooling and chilling water circulation systems for central air conditioners, chillers and refrigerators; industrial and civil cooling water, industrial cooling water circulation systems; circulation systems for bathing and heating using geothermal water.

Filtration media

Removal of various sticky substances, gum particles, silt and other mechanical impurities from water.

How does the backwash filter work?

Typically, the steering valve remains open during regular operation, allowing water to pass through the filter cartridge and exit from the outlet. However, when the drain valve station is activated, the overall liquid flow through the filter increases, resulting in a higher flow rate. This increased flow dislodges impurities adhering to the filter walls, which are then flushed out through the drainage outlet. Subsequently, when the steering valve is closed and the drainage valve is opened, water is directed to the exterior of the filter cartridge from the inlet section mesh. While most of the water exits through the outlet, a portion enters the interior of the filter cartridge from the exterior mesh of the impurity collection section. This process initiates a backwash action on the filter cartridge, effectively flushing impurities adhering to the mesh from the exterior. Despite this, residual impurities continue to be discharged through the drainage outlet.

What is Product Advantages

Automatic Backwash System:

Featuring a modular design that facilitates forward filtration and reverse backwashing, our system boasts a multi-core structure with a large filtration area. This design enables it to effectively handle fluctuations in water quality and automatically initiate backwashing when necessary.

Automation Control System:

Our intelligent control system is highly responsive and precise, offering an intuitive interface that is easy to operate.

High-Performance Precision Filter Element:

Utilizing a V-shaped gap precision filter element, our system excels in backwashing effectiveness. This design is particularly adept at filtering pollutants and impurities that are challenging to remove, such as microfiltration, sludge, and soft agglomerations.

Overall Structural Advantages:

With a structure that requires no consumables and features minimal wearing parts, our system ensures low operating costs and long-term reliability.

Technical parameters

Housing: Carbon steel, SS304 , SS316L

Housing: Carbon steel, SS304 , SS316LStrainer: SS304, SS316L

Brush holder: SS304 , SS316LDischarge valve: cast iron, stainless steel

Controller: CopperSealing ring: PTFE

Can be customized according to different working conditions

Automatic backwash filters are crucial in industrial processes for several reasons:

Efficient Filtration: The modular design and large filtration area of these filters ensure efficient removal of impurities and contaminants from the water, maintaining high water quality standards.

Continuous Operation: With the ability to automatically initiate backwashing, these filters can maintain optimal performance even in environments with fluctuating water quality, ensuring uninterrupted operation of industrial processes.

Cost-Effectiveness: The intelligent automation control system minimizes manual intervention and reduces the need for consumables, resulting in lower operating costs over time.

Precision Filtration: High-performance precision filter elements, such as V-shaped gap filters, ensure thorough removal of challenging pollutants and impurities, contributing to the overall quality of the filtered water.

Reliability: The overall structure of automatic backwash filters is designed for durability and longevity, with fewer wearing parts and minimal maintenance requirements, enhancing the reliability of industrial processes.