The application of shallow sand filters in the power industry is mainly focused on the water purification treatment of circulating cooling water systems in power plants. The specific performance is as follows:

Cooling water treatment: In the production of the power industry, especially thermal power plants and nuclear power plants, a large amount of cooling water is needed to cool the units, and this cooling water will take away a lot of heat during use, and it will also take away some pollutants. Shallow sand filters can effectively filter the cooling water, remove particulate matter, and ensure the cleanliness of the cooling water.

Boiler feed water treatment: If there are impurities in the boiler feed water, it will seriously affect the operating efficiency of the boiler and even cause damage to the equipment. The role of the shallow sand filter here is to filter out these tiny particle impurities and improve the purity of the feed water, thereby improving the operating performance of the boiler and extending the service life of the equipment.

Environmental protection equipment cooling water treatment: Back-pressure shallow sand filters can be used in the cooling water circulation system of environmental protection equipment, such as flue gas denitrification, desulfurization devices, etc., to filter out particulate pollutants and ensure the normal operation of the equipment and environmental protection standards. Stable and up to standard.

In general, the power industry will face various problems caused by poor water quality, and the application of shallow sand filters can effectively solve these problems and show strong industrial application value.

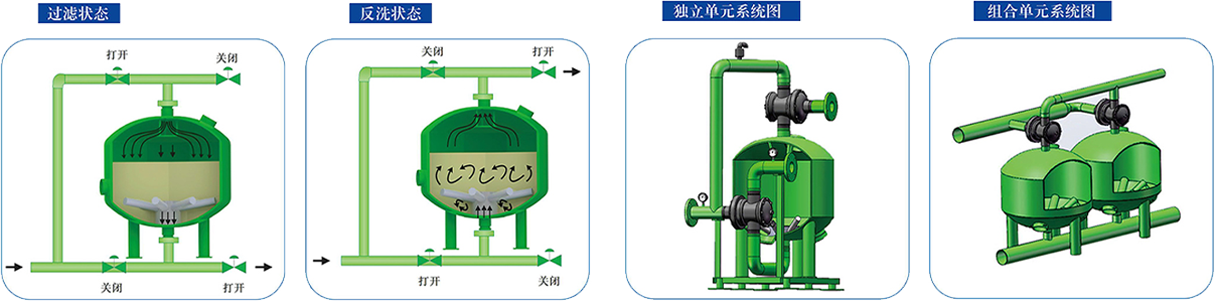

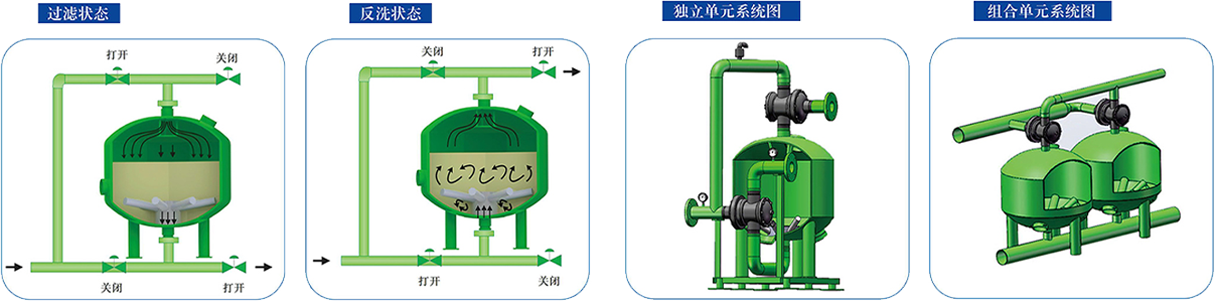

The working principle of a shallow sand filter is relatively simple. It mainly uses the physical properties of sand to capture and remove suspended particle impurities in the water.

The specific workflow of the shallow sand filter is as follows:

Wetting phase: First, an untreated water source is introduced into the sand bed. This step is called the "wetting stage" and the purpose is to wet the sand bed enough to accept filtration.

Filtration stage: After the wetting stage, water begins to flow normally through the sand bed and enters the filtration stage. At this time, the suspended solids in the water will be "trapped" by the sand because the diameter of the suspended solid particles is larger than the gap between the sand. Water and impurities smaller than the particles will pass through the sand bed and flow out of the filter.

Backwash stage: After a period of time, the filtered suspended solids will gradually accumulate on the sand bed, reducing the filtration efficiency and even causing the filter to become clogged. Therefore, a regular "backwash" step is required, that is, flushing the sand bed through clean water in reverse to remove impurities attached to the sand. After backwashing, the filter is ready for use again.

This is basically how a shallow sand filter works. To put it simply, it uses the gaps in the sand to trap suspended solids and clean the water source.

As a commonly used filtration equipment, shallow sand filter has advantages in many aspects

Highly accurate filtration capacity: Generally speaking, shallow sand filters can effectively filter out suspended particles with diameters ranging from 0.01 to 100 microns. This highly precise filtration capability ensures the purity of water quality, and can achieve ideal filtration effects whether it is used for industrial desalted water treatment, cooling water, boiler feed water, or drinking water treatment.

Simplified operation and maintenance: The shallow sand filter is designed with ease of operation and convenient maintenance in mind. The filter is generally equipped with a mud discharge valve. After the impurities in the filter layer accumulate to a certain extent, the initial filtration state can be restored through simple backwashing. Its structure is also relatively simple, and it does not require too professional skills to perform daily operation and maintenance.

High efficiency and large capacity: Due to the use of physical filtration, the shallow sand filter's water treatment volume and filtration speed greatly exceed other filtration methods under the same area. Therefore, for industrial fields such as electric power, metallurgy, and chemicals that require large-scale water quality treatment, the use of shallow sand filters can greatly improve work efficiency.

Stable equipment life and low operating costs: Generally speaking, the sand changing cycle of the sand filter bed can last for several years or even more than ten years, and has a long service life. In addition, even if the sand needs to be replaced, the cost is relatively low. Therefore, under long-term operation, both equipment depreciation expenses and operation and maintenance costs are relatively low.

Wide applicability: The shallow sand filter has a simple working principle and can be applied to various complex water quality conditions. Whether it is natural water sources, groundwater, seawater desalination pretreatment, or various industrial wastewater, cooling water and other complex water quality problems, you can find the most suitable filtration solution by adjusting parameters such as backwash intervals and sludge discharge frequency.

Therefore, shallow sand filter is an excellent filtration equipment in many aspects and is widely used in various industrial fields.

The shallow sand filter is actually composed of one or more filter tanks connected in parallel. The main structure can be summarized as the following parts

Canister (housing): This is the main part of the filter and serves as a container for all other components. Made of materials that are corrosion-resistant and can withstand a certain amount of pressure, such as carbon steel, stainless steel, plastic or fiberglass.

Water inlet pipe and water outlet pipe: They are mainly responsible for transporting the water source to be treated to the inside of the filter tank and exporting the filtered clean water. Usually there is a valve for switch control.

Filter material: The filter material is usually called the filter layer, which is mainly composed of sand and gravel. The particle size and proportion of sand and gravel are carefully designed to achieve excellent filtration effects. During the filtration process, the water to be treated enters from the water inlet pipe, and then flows through the filter material sequentially from top to bottom, and relevant impurities are intercepted in the filter material.

Water distributor and water collector: The water distributor is mainly used to form a uniform water flow distribution to ensure that the water flow can evenly pass through the filter layer to improve the filtration efficiency; while the water collector (filter cap) is located at the bottom of the tank and is mainly used for to receive and export filtered water. During the backwashing process, the water collector can evenly distribute the backwash water on the filter layer to clean the filter layer.

Sewage pipes and valves: This includes electric/magnetic three-way valves, butterfly valves, etc., which are mainly used to assist in the backwash process and regularly remove impurities accumulated in the filter layer.

Control cabinet, differential pressure switch, pressure gauge, exhaust valve, etc.: These components are mainly used to monitor and regulate the operating status of the filter, such as pressure monitoring, scheduled backwashing, fault alarm, etc.

Backwash equipment: Backwash equipment mainly includes backwash water sources, backwash valves, etc., which are used to clean and maintain the filter regularly to ensure the filtering effect and service life of the filter.

The above is the detailed structure of the shallow sand filter. Each part plays an important role, jointly ensuring the normal operation of the filter and excellent filtration effect.

The backwash program of the shallow sand filter can be started in a variety of ways, mainly including the following:

Manual button: Manually start the backwash program through the button or switch on the operation interface. This method is mostly used for regular maintenance or when a malfunction occurs and requires cleaning.

PLC control: A programmed logic controller (PLC) is used to automatically control the backwash process. Backwashing can be started regularly or quantitatively by setting the program.

Pressure difference start: When the system detects that the pressure difference between the inlet and outlet water of the filter reaches the preset threshold, the backwash program will be triggered. This method automatically monitors the working status of the filter to determine whether backwashing is needed.

Management system control: It is suitable for complex systems. The backwash program is controlled through the host computer or management system, and centralized control or remote control can be achieved.

The above are common ways to start the backwash program. Which method to use depends on the design of the filter and the requirements of the use environment. No matter which method is used, backwashing is critical to maintaining filter operating efficiency and longevity.