Targeted Solutions for Transfer Points, Crusher Houses & Bunkers - Pulse Jet Bag Dust Collector

The Invisible Threat: Coal Dust in Conveying Lines

Persistent dust plumes in unloading ditches, hazy transfer stations, and powdered crusher rooms plague coal-handling operations. Beyond health hazards and explosion risks, uncontrolled dust emissions violate stringent environmental standards. Taming this "dust dragon" demands precision targeting at its source.

Three Primary Culprits of Coal Dust

1. Dry Raw Coal: The Accomplice

When surface moisture falls below 7%, fine coal particles liberate freely during transfers and drops.

2. "Induced Airflow": The Amplifier

At high-drop transfer points or crusher stations, fast-moving coal streams entrain air, creating pressurized turbulence within enclosed chutes that forces dust through gaps.

3. Seal Failures: The Escape Route

Belt misalignment and equipment vibration compromise chute seals, allowing dust-laden air to escape under positive pressure.

Core Challenge:

Inadequate sealing + induced positive pressure = primary dust dispersion mechanism.

Segment-Specific Dust Control Solutions

1. Unloading (Rail/Truck)

Pain Point: Open-air operations with high-impact drops trigger instant dust plumes.

Solution: Dual-Fluid Spray Suppression System

Ultra-fine mist instantly agglomerates dust particles

Pipe insulation critical in cold climates (higher CAPEX but reliable for exposed areas)

[Diagram: Spray nozzles positioned above rail/truck unloading zone]

2. Transfer Stations & Crusher Houses

Pain Point: Multi-level drops and vibrating equipment create high dust risk.

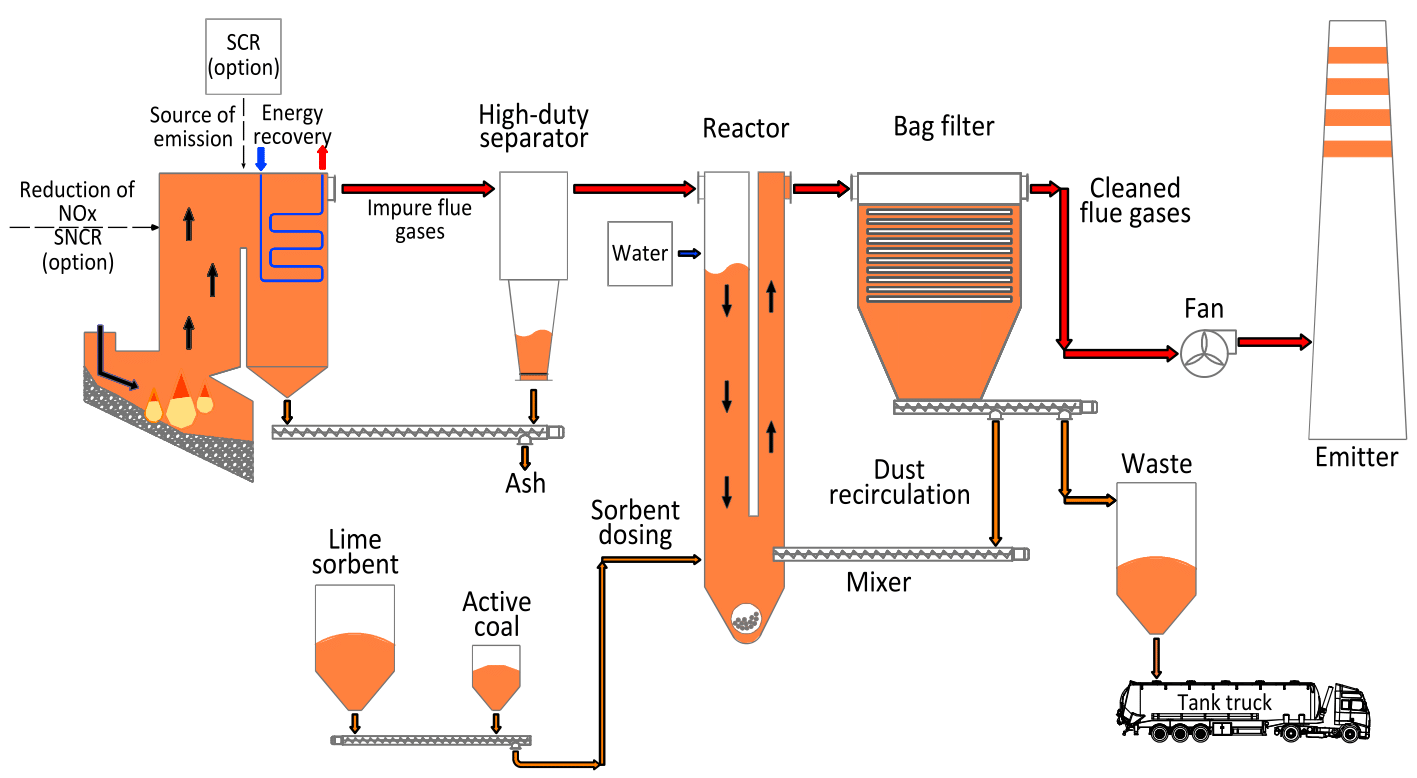

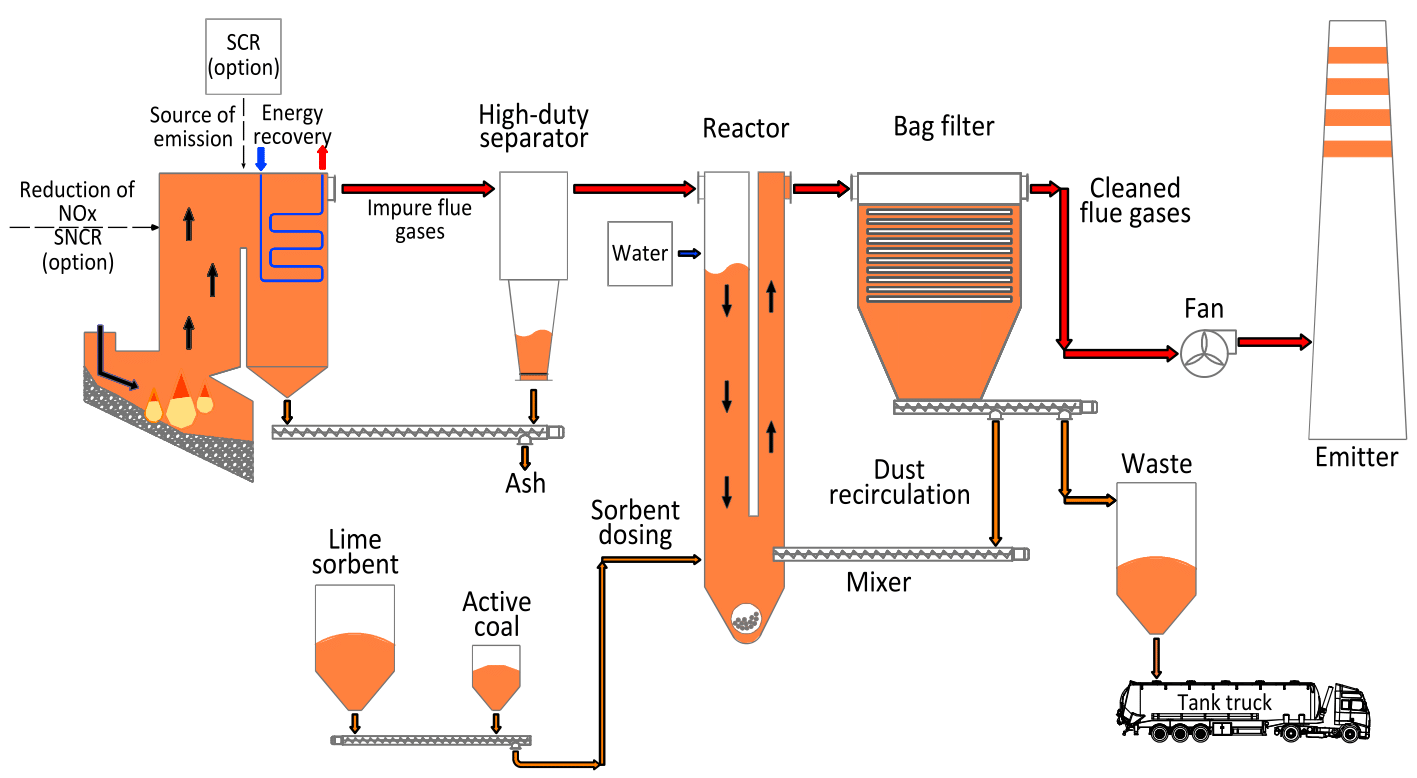

Solution A: Baghouse Dust Collector + Supplemental Spray (Proven Efficiency)

Head chute sprays suppress initial dust lift-off

Tail section negative-pressure extraction captures fugitive dust

Exit sprays reinforce containment

Advantage: High-efficiency compliance with strict standards

Consideration: Larger footprint, higher CAPEX/OPEX

3. Coal Bunkers (Plow Feeders)

Pain Point: Turbulent air currents create upward dust flow from positive pressure.

Solution: Micro-Power Baghouse + Targeted Spray

Three Pillars of Effective Dust Control

1. Source Containment: The Foundation

Hermetic sealing of transfer chutes eliminates primary escape paths.

2. Pressure Management: The Key

Neutralizing induced airflow through:

3. Technology Integration: The Multiplier

Synergizing spray systems, baghouse/micro-collectors, and structural engineering achieves end-to-end control.