What is Ultra-filtration equipment?

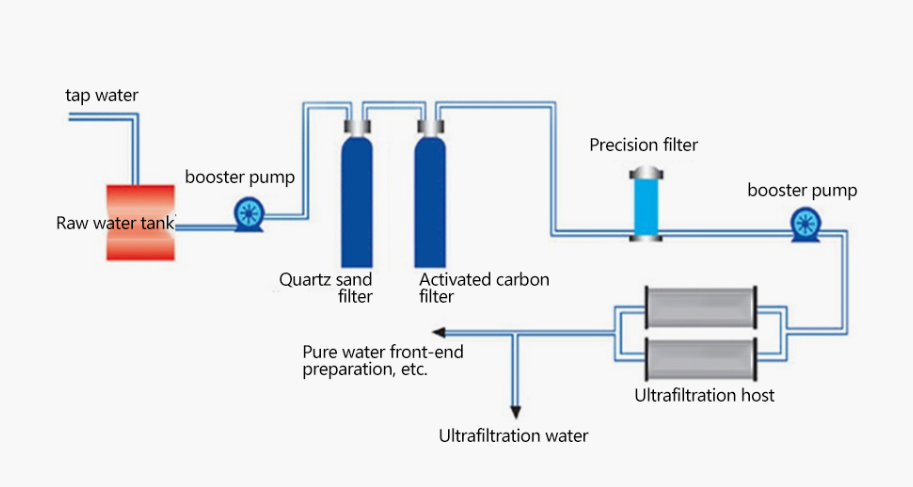

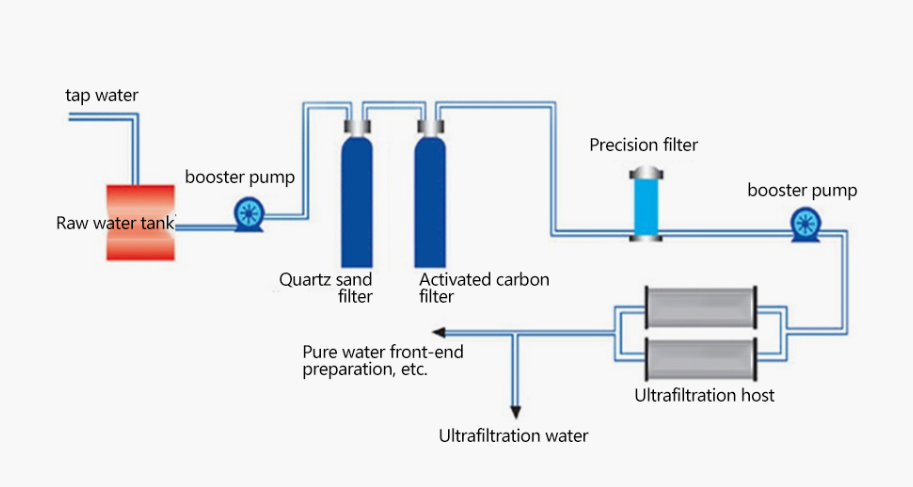

Ultra-Filtration (UF) is a state-of-the-art technology used for the purification and separation of solutions. This system employs an ultrafiltration membrane system which uses fine membrane filaments as a medium for filtration.

The driving force behind this process is the pressure difference created on both sides of the membrane. This differential pressure allows only certain components of the solution, such as the solvent (for instance, water molecules), inorganic salts, and small organic molecules, to pass through the UF membrane.

On the other hand, larger molecules like suspended matter, colloids, proteins, and microorganisms present in the solution are effectively retained. This selective permeability allows for a high degree of purification or separation, making UF an efficient and reliable method for treating various types of solutions.

What is the working principle of ultra-filtration?

Ultrafiltration is a sophisticated membrane separation process that is based on the principle of sieving. It's powered by a pressure differential which allows it to achieve a filtration precision within the range of 0.005-0.01 μm. This fine level of precision enables it to effectively remove various impurities from water, including particles, colloids, bacteria, heat sources, and high molecular organic substances.

The potential applications of ultrafiltration are vast due to its ability to perform a range of operations such as the separation, concentration, and purification of substances. This makes it a highly versatile technology that can be utilized in a wide range of industries, from water treatment to food production and pharmaceuticals.

One of the distinguishing features of the ultrafiltration process is that it operates without inducing any phase transformations, meaning it can be conducted at room temperature. This is particularly beneficial when dealing with heat-sensitive substances, as it ensures that their structural integrity and properties are not compromised during the filtration process.

Furthermore, ultrafiltration systems are designed to withstand various conditions, exhibiting excellent resistance to temperature fluctuations, acidic and alkali environments, and oxidative reactions. This robustness contributes to the system's reliability and durability, making it an ideal choice for long-term, continuous operations.

Moreover, the ultrafiltration process is not only efficient but also environmentally friendly. It doesn't require the use of any chemicals, which reduces the risk of contamination and makes the process more sustainable. This aligns with the increasing emphasis on green technology and sustainable practices in industrial operations.

In conclusion, ultrafiltration is a powerful and versatile technology that offers a reliable and sustainable solution for the purification and separation of solutions in various industries.

What are the product advantages of ultrafiltration?

High Recovery Rate:

A significant advantage of ultrafiltration is its high recovery rate. This system can be individually designed to meet the user's specific requirements, ensuring that it can function optimally under a variety of conditions. Advanced control software is incorporated to ensure the long-term stable operation of the system, enhancing its operational efficiency and reliability.

Compact Structure:

The ultrafiltration system boasts an advanced process design, resulting in a high degree of integration. It has a compact structure, which means it requires a smaller footprint compared to conventional filtration systems. This compactness, coupled with its user-friendly design, makes operation and maintenance a breeze, reducing the labour intensity for the workers.

Individual Design:

One of the defining features of the ultrafiltration process is that it solely relies on pressure as the driving force for membrane separation. This results in a simplification of the separation unit and shortens the processes involved. This simplicity makes it easy to operate, control, and maintain the system, adding to its appeal.

Ease of Use:

The ultrafiltration equipment is designed with user convenience in mind. It's easy to use, and its effective purification capabilities make it suitable for a variety of applications. Whether it's in a residential, commercial, or industrial setting, ultrafiltration can deliver top-notch performance, providing clean, purified solutions efficiently and reliably.

Ultrafiltration equipment can be utilized in a wide range of industries and applications due to its efficient separation and purification capabilities. Here are some key areas where it's commonly used:

Water and Wastewater Treatment: Ultrafiltration is extensively used in water treatment plants for the removal of bacteria, viruses, and other contaminants. It's also used in wastewater treatment to filter out large particles before the water undergoes further treatment.

Food and Beverage Industry: In the food and beverage industry, ultrafiltration is used for clarification of fruit juices, wine and beer, separation of proteins, and concentration of dairy products.

Pharmaceutical Industry: Ultrafiltration plays a crucial role in the production of pharmaceutical products. It's used for the concentration and purification of proteins, vaccines, and antibiotics, as well as the removal of pyrogens from water.

Chemical Industry: In the chemical industry, ultrafiltration is used for the recovery of precious metals, recycling of acids and bases, and separation of different sized molecules in a solution.

Healthcare: Ultrafiltration is used in dialysis machines to filter out waste products from the blood of individuals with kidney failure.

Desalination: Ultrafiltration serves as a pre-treatment stage in desalination plants, helping to remove larger particles before the water is treated with reverse osmosis.

Electronics: The electronics industry uses ultrafiltration in the production of semiconductors and other components where ultra-pure water is required.

These are just a few examples, and the use of ultrafiltration equipment extends to many other sectors as well, including the automotive, textile, and oil industries, among others.