The world of industrial operations is massively dynamic and requires reliable and efficient machinery. Hydraulic systems form a significant cornerstone in a broad range of industries, including machining operations, petrochemical processes, metallurgy, textiles, electronics, and pharmaceutical production. Owing to their pivotal role, it is crucial for these systems to integrate superior components to achieve optimal operational efficiency and longevity. A key part of the solution to high-performing hydraulic systems is the TFB Series oil suction filter.

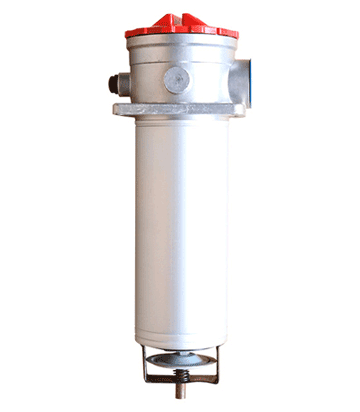

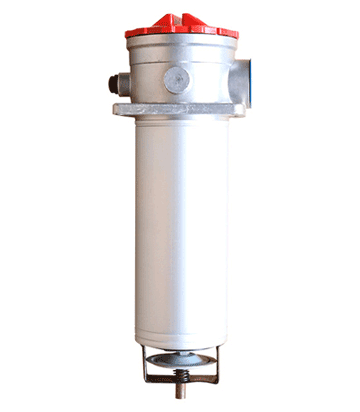

Renowned for high filtration accuracy, large oil capacity, and impressive pollutant carrying capacity, the TFB Series oil suction filter stands as a testament to engineering excellence and performance optimization in hydraulic systems. Designed for high precision oil absorption filtration, it is instrumental in ridding hydraulic oil of potential contaminants like metal particles and colloidal substances before oil absorption. This function is vital in prolonging the lifespan of hydraulic oil and by extension, the oil pump.

Applications

The versatility of the TFB series oil suction filter is reflected in its wide-ranging applications, primarily the hydraulic systems of heavy machinery, mining machinery, and metallurgical machinery. Beyond this, its benefits can also be extended to hydraulic systems in the machining operations, metallurgical industry, petrochemical industry, textile industry, electronics, and pharmaceutical production. Users can customize the oil suction filter according to their specific working conditions, underscoring the user-friendly design approach that goes into this incredible product.

Filter Medium

A primary component contributing to the functionality of the TFB series oil suction filter is the filter medium, which constitutes water and ethylene glycol in hydraulic oil. This combination effectively traps pollutants present in the hydraulic system, thereby ensuring the quality of the oil being transmitted for the system's operation.

Customizing the TFB series oil suction filter to match different working conditions can provide many significant benefits. Here are a few:

Optimized Performance: Each working environment has unique characteristics, such as different types or levels of pollutants or specific operating temperatures. When the oil suction filter is customized to match these conditions, it can perform more efficiently, effectively filtering out specific contaminants and withstanding value performance under specific operating conditions.

Extended Equipment Life: Customizing the suction filter optimizes its effectiveness, helping prevent damage to the hydraulic system from pollutants and thus extending the life of the system and reducing the need for repairs or replacements.

Improved Efficiency: A customized filter can be designed with the right balance of filter area, pore size, and other parameters to provide optimal filtration efficiency without impeding oil flow in the system.

Cost Savings: Tailoring the filter to the specific needs of the working conditions means it's not over- or under-designed. This yields cost savings both in terms of the filter itself and the potentially reduced downtime and maintenance costs due to improved protection of the hydraulic system.

Greater Flexibility: Customization allows for variations in filter design and placement to accommodate physical constraints or needs of the system, such as size or mounting location.

Environmental Suitability: A custom-designed filter provides the perfect opportunity to consider environmental factors such as climate, which could affect the performance of the hydraulic system and the filter. Variations in filtering materials or structures could provide the best results for hot, cold, humid, or dusty conditions.

In summary, having a TFB series oil suction filter customized to meet the precise requirements of your specific working conditions can offer immense benefits, contributing to the effective, efficient, and cost-effective operation of your hydraulic system.

Customizing the TFB series oil suction filter to match different working conditions can provide many significant benefits. Here are a few:

Optimized Performance: Each working environment has unique characteristics, such as different types or levels of pollutants or specific operating temperatures. When the oil suction filter is customized to match these conditions, it can perform more efficiently, effectively filtering out specific contaminants and withstanding value performance under specific operating conditions.

Extended Equipment Life: Customizing the suction filter optimizes its effectiveness, helping prevent damage to the hydraulic system from pollutants and thus extending the life of the system and reducing the need for repairs or replacements.

Improved Efficiency: A customized filter can be designed with the right balance of filter area, pore size, and other parameters to provide optimal filtration efficiency without impeding oil flow in the system.

Cost Savings: Tailoring the filter to the specific needs of the working conditions means it's not over- or under-designed. This yields cost savings both in terms of the filter itself and the potentially reduced downtime and maintenance costs due to improved protection of the hydraulic system.

Greater Flexibility: Customization allows for variations in filter design and placement to accommodate physical constraints or needs of the system, such as size or mounting location.

Environmental Suitability: A custom-designed filter provides the perfect opportunity to consider environmental factors such as climate, which could affect the performance of the hydraulic system and the filter. Variations in filtering materials or structures could provide the best results for hot, cold, humid, or dusty conditions.

In summary, having a TFB series oil suction filter customized to meet the precise requirements of your specific working conditions can offer immense benefits, contributing to the effective, efficient, and cost-effective operation of your hydraulic system.

Optimizing the lifespan of the TFB series oil suction filter based on specific operating conditions has several key benefits:

Improved Efficiency: A filter designed for a specific working condition will operate at optimal efficiency for its designed lifespan, ensuring pollutants are effectively removed throughout its life. This helps in maintaining the peak performance of the hydraulic system.

Extended Equipment Life: An optimized life expectancy of the filter will prevent situations where a worn-out or clogged filter might allow undue pollutants into the system. By reducing the chances of contamination, the life of the entire hydraulic system can be prolonged.

Cost and Time Savings: Filters that are changed too frequently can lead to wasted resources in terms of money and time spent on premature filter replacements. On the other hand, leaving a filter unchanged for too long can lead to increased wear and tear on the system and potential damage. By optimizing the lifespan of the filter to match its operational environment, unnecessary costs can be avoided.

Less Downtime: Predictable filter lifespan according to specific operating conditions allows for more efficient scheduling of preventive maintenance and filter replacement. This helps in reducing unplanned downtime, enabling continuous and smooth production.

Environmental Responsibility: Ensuring a filter’s lifespan is aligned with its operational environment means fewer filter replacements. Less frequent replacements translate into less waste, which aligns with sustainable and environmentally responsible practices.

To summarize, by optimizing the lifespan of your TFB series oil suction filters for the specific working conditions of your hydraulic system, you can significantly enhance system efficiency, reduce costs, and maximize sustainability.

Optimizing the lifespan of the TFB series oil suction filter based on specific operating conditions can greatly improve the efficiency of your hydraulic system:

Maintain Peak Performance: A filter that's engineered to perform optimally in certain functioning conditions would be able to maintain the peak performance of the hydraulic system for a longer time, ensuring smooth operation and less energy consumption.

Continuous Oil Flow: Filters that are not replaced regularly can become clogged and obstruct oil flow, compromising the system's performance. In contrast, if it's known how long a filter can function effectively in a particular environment, the replacement can be scheduled just as its efficiency starts to diminish, ensuring a continuous flow of clean oil.

Reduced Wear and Tear: By consistently keeping potentially damaging contaminants out of the hydraulic system, an adequately performing filter can reduce the overall wear and tear on the system components. This leads to fewer system failures and less need for repair or replacement of components, thus improving overall operational efficiency.

Predictable Maintenance: Knowing the optimal lifespan of a filter under specific conditions allows for predictable maintenance, so filters can be replaced before they become less effective, thereby preventing downtime and maintaining the efficient operation of the hydraulic system.

Therefore, optimizing the lifespan of your filter according to specific operating conditions not only extends the life of the filter itself but also enhances the overall efficiency of the hydraulic system it supports.

By optimizing the lifespan of the TFB series oil suction filter based on specific operating conditions, energy consumption can be reduced in several ways:

Smooth Operation: An optimized filter ensures that the hydraulic system operates smoothly, without the stress and strain caused by blocked or clogged filters. When the system runs smoothly, it can perform its tasks with less effort and consequently less energy.

Preventing Damages: By preventing damages to the hydraulic system that could result from a poorly performing filter, the system maintains its peak operational efficiency for a longer period. A smoothly operating system uses energy more efficiently compared to a system that's dealing with wear and tear.

Consistent Oil Flow: A clogged filter can obstruct the oil flow, forcing the hydraulic system to work harder and consume more energy to maintain its function. By changing the filter optimally, these obstructions can be prevented ensuring a consistent, unobstructed flow of oil and optimal energy utilization.

Enhanced System Performance: An optimized filter can maximize the performance of hydraulic systems and machinery. Systems that are working at their intended efficiency typically consume less energy than systems that are operating under strain or working harder due to inefficient filtration.

Scheduled Maintenance: Knowing the effective lifespan of a filter allows for maintenance to be scheduled around peak demand times, minimizing energy waste during periods of reduced activity or system downtime.

In these ways, the optimization of a filter's lifespan can help ensure lasting efficient performance of the whole system, and contribute significantly towards energy conservation.

In a hydraulic system, consistent oil flow and optimal energy utilization are closely related:

Smooth Operations: Consistent oil flow allows for smooth and uninterrupted operations of the hydraulics, which leads to the entire system working more efficiently. This in turn allows the system to achieve the desired output with less energy consumption.

Prevention of Overworking: If the oil flow is obstructed due to a clogged filter or other issues, the system has to work harder to maintain the desired output. This leads to increased energy consumption. Consistent oil flow prevents this from happening, thus maintaining optimal energy utilization.

Consistent Pressure Maintenance: In hydraulic systems, oil is often used to transmit power by means of changing pressures. Consistent oil flow ensures that there's always the right amount of medium available to maintain the necessary pressure level, which optimizes energy usage.

Reduced Wear and Tear: Consistent oil flow also helps in reducing wear and tear on system components. By preventing start-stop cycles and sudden pressure changes that can lead to mechanical strain on components, consistent oil flow aids in maintaining energy efficiency.

Temperature Management: Hydraulic oils also play a critical role in managing the temperature within the system. A consistent oil flow aids in dissipating heat and maintains the system's temperature, ensuring components perform optimally and don't lose efficiency due to overheating, thus saving energy.

In conclusion, by maintaining a consistent oil flow, hydraulic systems can operate with less strain, maintain steady pressure, manage temperatures, and reduce wear and tear, all of which contribute to optimal energy utilization.

Temperature management is pivotal in ensuring optimal energy utilization in hydraulic systems for several reasons:

Efficient Performance: Hydraulic systems are designed to operate within a specific temperature range. If the oil temperature becomes too high, it can become less viscous, reducing the system's performance and making it work harder - using more energy in the process. Conversely, if the temperature is too low, the oil can become too viscous, again impairing system performance and causing increased energy consumption.

Component Lifespan: Overheating and excessive fluctuations in temperature can contribute to the degradation and premature failure of system components, which can incur downtime, repairs, and replacements, all of which indirectly increase the overall energy consumption due to inefficiency and interruption of operation.

Preventing Thermal Breakdown: High temperatures can cause thermal breakdown of hydraulic fluids, decreasing their lubrication properties and leading to increased friction, wear and tear, all of which necessitate more energy for the system to work.

Optimal Oil Performance: Hydraulic oils often have an optimal operating temperature range, within which they provide the best lubrication and flow properties. By maintaining this optimal temperature, the system can operate at its most efficient state, leading to better energy utilization.

Seal Condition: The condition and effectiveness of seals within the hydraulic system can be adversely affected by excessive temperatures, leading to leaks and system inefficiency. Proper temperature management can prevent this, helping to ensure that the system functions optimally and uses energy efficiently.

Overall, good temperature management in hydraulic systems ensures the system is operating at optimal performance levels, thus increasing energy efficiency. It eliminates unnecessary strain on the system, prolongs its lifespan, and ensures the best performance from the hydraulic oil and system components.

Overheating can have several severe consequences on the lifespan of hydraulic system components:

Thermal Degradation: High temperatures can cause thermal degradation of hydraulic fluids, reducing their lubrication properties. This may lead to increased friction between component surfaces, accelerating wear and tear and reducing the components' lifespan.

Material Fatigue: High temperatures can induce material fatigue, especially in metal parts. Over time, this fatigue can contribute to weakening and failure of these components.

Seal Deterioration: Heat can deteriorate seals within the hydraulic system, making them less effective. Leaks may occur as a result, reducing system pressure and efficiency, and causing premature wear and damage to the system components.

Component Deformation: Excessive heat can cause component deformation and expansion. Parts may not fit or work together as intended, leading to inefficient operation and faster wear and tear.

Accelerated Oxidation: Overheating can accelerate the process of oxidation, leading to rusting and contamination of the hydraulic fluid. Contaminants can wear away at and damage system components over time.

Prevention of Heat Dissipation: Hydraulic systems, like any mechanical system, generate heat during operation. If a system consistently overheats, it may indicate that the system is unable to effectively dissipate that heat, which can lead to accelerated wear and damage to system components.

By implementing effective temperature management strategies to prevent overheating, the lifespan of components in hydraulic systems can be substantially extended, resulting in more reliable operation, fewer repair and replacement costs, and improved overall efficiency.

Component deformation due to overheating can significantly impact the efficiency of a hydraulic system in several ways:

Disturbed Flow: When components become deformed due to heat, it can disturb the flow of hydraulic fluid. For a hydraulic system to work efficiently, the fluid needs to flow smoothly. Irregularities in flow patterns due to deformation can lead to power loss and energy inefficiency.

Increased Friction: Deformed parts may not fit together as smoothly as they initially did. This can lead to increased friction between components, causing the system to work harder and thus consume more energy.

Seal Failure: If components associated with seals or elements that maintain pressure become deformed, they can lead to the failure of these seals. A seal failure often results in leaks and reduces system pressure – both of which impair the efficiency of a hydraulic system.

Increased Wear and Tear: Deformed components are likely to suffer from increased wear and tear, as the deformed shape leads to unequal distribution of stress across their surface. This increased wear can further degrade the component, accelerating the decline in system efficiency.

System Downtime: Component deformation could lead to system failures requiring extensive maintenance and repair, causing substantial system downtime. This negatively impacts the overall efficiency of a hydraulic system, as it's not productive during these periods.

Preventing overheating and thus component deformation is key in maintaining the efficiency of a hydraulic system. Regular maintenance checks, ensuring adequate cooling measures, and using heat-resistant materials can all help in preventing component deformation and maintaining system efficiency.

Seal failure due to component deformation can have a serious impact on the efficiency of a hydraulic system. Here's how:

Fluid Leakage: One of the primary purposes of seals in a hydraulic system is to prevent fluid leakage. Should there be a seal failure, hydraulic fluid can start to leak from the system. This would mean that there is less fluid to transmit power, leading to a decrease in system efficiency.

Pressure Reduction: Hydraulic systems rely on the pressure generated by the hydraulic fluid to do work. If a seal fails, this pressure can be lost. As pressure decreases, so does the system's ability to do work, thereby reducing the efficiency of the system.

System Downtime: Seal failures often require the hydraulic system to be shut down for repair or maintenance. This downtime not only disrupts operation but can result in lower overall efficiency and productivity.

Increased Wear and Tear: Leaks caused by seal failures can lead to the improper lubrication of moving parts, resulting in increased friction and hence increased wear and tear on these components. This can lead to premature failure of components, reducing the overall lifespan and effectiveness of the system.

Contamination risk: Seal failures can also open up the system to contamination risk. Dirt, dust, and other particles can make their way into the hydraulic fluid when a seal fails. Contaminated hydraulic fluid can cause damage to system components and reduce the overall efficiency of the system.

Overall, maintaining the seals in good working order is vital to keeping a hydraulic system running efficiently. Regular check-ups, preventive replacement, and choosing high-quality seals can help prevent seal failures and maintain the efficiency and longevity of your hydraulic system.

Choosing high-quality seals for a hydraulic system plays an integral role in promoting its efficiency and longevity. Here are some ways how:

Better Material Resistance: High-quality seals are manufactured from materials that can resist harsh conditions such as high pressure, high temperature and chemical abrasion from hydraulic fluid. This resistance helps the seals to maintain integrity and performance over extended periods, resulting in less downtime and replacements.

Reduced Leakage: High-quality seals provide superior sealing performance, resulting in minimal fluid leakage. This helps maintain the required pressure within the hydraulic system for efficient operation. Reduced leakage also ensures less wastage of hydraulic fluid and reduced operational costs.

Extended Seal Lifespan: High-quality seals typically have a longer lifespan than their low-quality counterparts. They can withstand the tough operating conditions of a hydraulic system for longer, reducing the frequency of seal replacements.

Improved Component Protection: A high-quality seal helps to protect the whole system. It prevents contaminants from entering the hydraulic system, thereby reducing wear and tear on components and elongating their lifespan.

Maintained System Efficiency: Because high-quality seals effectively hold pressure and prevent fluid leakage, they help the system maintain its operational efficiency.

Reduced Maintenance Costs and Downtime: With their improved durability and performance, high-quality seals can lead to less frequent maintenance requirements, and thereby lower costs and minimized system downtime.

In summary, while high-quality seals may come with a higher upfront cost, their long-term benefits of improved efficiency, reduced maintenance, and increased component and system lifespan can ultimately lead to cost savings, making them an invaluable investment for your hydraulic system.

High-quality seals in a hydraulic system provide protection to the components in several significant ways:

Preventing Contamination: High-quality seals form a tight barrier that prevents foreign particles or contaminants from entering the hydraulic system. This is crucial as dirt, dust, or any foreign particles can cause significant wear and tear on the system components if they get mixed with the hydraulic fluid.

Maintaining Lubrication: The hydraulic fluid, in addition to its primary job of transmitting power, also serves as a lubricant for various moving parts in the system. By preventing fluid leakage, high-quality seals ensure that there is always an appropriate level of lubrication, thus reducing friction and subsequent wear and tear between moving parts.

Ensuring Optimal Pressure: Seals in a hydraulic system maintain the pressure necessary for the functioning of the system. By doing so, they prevent damage and excessive wear and tear that can occur when components operate under sub-optimal pressure conditions.

Reducing Heat Generation: By ensuring optimal system pressure and efficient operation, high-quality seals help minimize heat generation within the system. Excessive heat can cause component deformation and wear, so by keeping heat levels under control, seals help protect the components.

Preventing Damage from Vibration or Shock: High-quality seals can absorb and dampen some of the vibrations or shock loads that may occur within a hydraulic system. This prevents these forces from causing excessive stress and consequent wear and tear on the components.

In summary, the quality of seals used in a hydraulic system plays a crucial role in maintaining system efficiency, prolonging component life, and protecting the system from wear and tear.

High-quality seals are specifically designed and made of materials that allow them to absorb and dampen vibrations and shock loads in hydraulic systems. The following are ways they accomplish this:

Viscoelastic Properties of Seal Material: The materials used to create high-quality seals, such as rubber and certain polymers, have viscoelastic properties. When subject to vibrations or shock loads, these materials can stretch, compress, and deform temporarily to absorb the energy, then return to their original form. This characteristic helps to effectively dampen the energy and reduce mechanical stress on other system components.

Cushioning Effect: Seals sandwiched between the components of the hydraulic system act like cushions. In case of shock loads, vibrations, or sudden pressure changes, they compress and expand, thereby absorbing energy and reducing the impact on other system components.

Seal Geometry: Higher quality seals often have a more intricate design and geometrical features, such as a double-lip profile, that are intended to help mitigate the effects of hydraulic pressure spikes and mechanical shock loads. These designs provide multiple paths for energy dispersal, reducing the overall impact on the seal and the surrounding components.

Elastic Recovery and Fatigue Resistance: High-quality seal materials also possess high elastic recovery and fatigue resistance. When subjected to repetitive or cyclic loads (such as vibrations), these materials can endure and resist material fatigue significantly better, increasing overall service life.

In summary, the capacity to absorb vibrations and shock loads is a critical feature of high-quality seals in hydraulic systems, helping to sustain overall system integrity and prolong component lifespan.