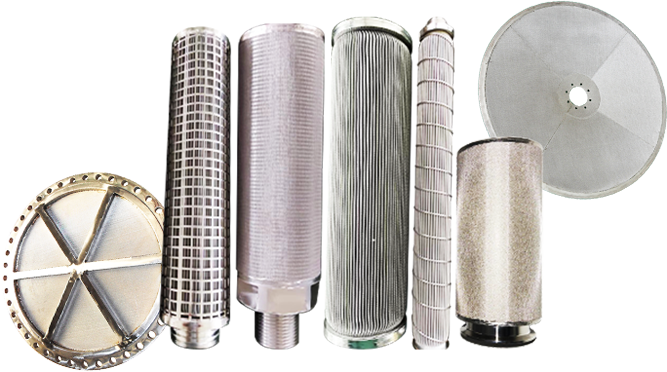

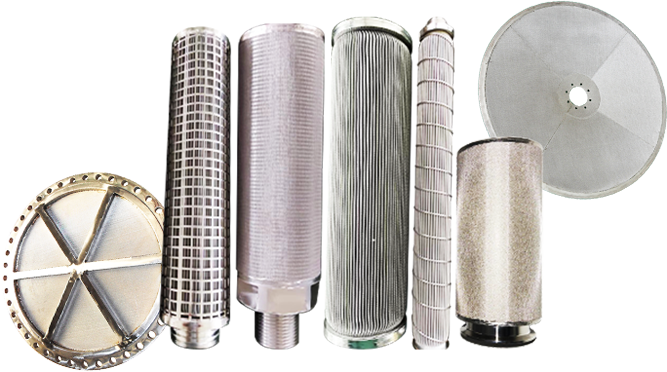

In the world of industrial filtration, innovation is constantly shaping new frontiers to overcome existing challenges, and metal powder filter cartridges have emerged as potent game-changers in this regard. By boosting efficiency, longevity, and adaptability, these cartridges are setting novel standards in various sectors, including water treatment, pharmaceuticals, food and beverage, chemical and petrochemical industries, as well as metallurgical processes.

At the heart of these innovative filter cartridges lies the employment of metal powder as the primary material. Unlike conventional filters, these cartridges are manufactured from finely powdered, sintered metal, typically stainless steel or titanium. This sintering process intersperses powdered metal at high temperatures in vacuum conditions, forging it into a robust structure with high mechanical endurance and comprehensive rigidity.

The cornerstone advantage of metal powder filter cartridges is their heightened filtration precision. They can achieve a filtration accuracy ranging from 1 to 300 microns, separating solid particles even at a micrometric level from various gases and fluids. This meticulous filtration accords industries the ability to uphold high-quality standards consistently.

Another notable feature of these cartridges is their customized design capability. In its essence, the fabrication process of these cartridges allows manipulation of the filter's structure to meet precise industry specifications. Be it the high-temperature conditions of metallurgical processes, acidic or alkaline environments in chemical industries, or sterile prerequisites of pharmaceutical productions, these cartridges can be tailored accordingly, facilitating operational flexibility across diverse applications.

Moreover, the large-diameter design and the centerless, one-way opening of these cartridges alongside the special interior-to-exterior liquid flow direction design ensure secure particle interception within the cartridge. Consequently, it can handle high volumes of contaminants with significant ease, reducing overall equipment investment and labor costs substantially.

Taking the case of the pharmaceutical industry, for instance, precision is crucial. The robustness of the metal powder filter cartridges allows them to offer incredibly accurate filtration. Impurities in the liquid or gas passage during production stand no chance of seepage, which ensures consistent, reliable, and safe productivity, adhering firmly to rigorous industry regulations.

Contrastingly, in industries like petrochemicals, enduring harsh environments is quintessential for maintaining operational efficiency. Metal powder filters, made from superior quality materials like 304/316/316L/304L stainless steel, exhibit excellent corrosion and heat resistance. These cartridges are proven to be robust alternatives, enduring high temperatures and acidic or alkaline conditions, maintaining their functionality and longevity.

When focusing on industrial applications, one cannot overlook the need for easy maintenance and sustainable operations. Metal powder filter cartridges edge past conventional options in this aspect, too. With their high mechanical strength and stainless construction, they can withstand backwashing or reverse blowing cleaning methods, making them reusable and more cost-effective in the long run. Plus, their simple, compact design ensures smooth installation and replacement processes, bringing down maintenance time and cost significantly.

The adaptability of these cartridges extends to their dimension customization as well. Be it any industry, the filtration needs significantly vary, and a one-size-fits-all approach doesn't suffice. These cartridges, apart from standard dimensions, can be custom-built according to user requirements, offering unparalleled service across different industrial applications.

In summary, metal powder filter cartridges are not just an alternative filtration solution; they represent a paradigm shift in industrial filtering techniques. With their high filtration precision, robust design, cost-effective operations, unhindered adaptability, and easy maintenance, they are redefining filtration standards. As industries globally continue to push for improved efficiency, enhanced safety, and reduced operational costs, the role of metal powder filter cartridges is set to become more indispensable. These revolutionary cartridges are indeed a testament to how innovation and adaptability are driving the future of industrial filtration.

Metal powder filter cartridges, made from premium quality materials like 304/316/316L/304L stainless steel, exhibit exceptional resistance to corrosion. This makes them suitable for acidic or alkaline conditions typically present in chemical processing industries. Their robust construction ensures they maintain functionality and longevity despite repeated exposure to harsh environments, offering consistent, reliable filtration performance.

The filtration precision of metal powder filter cartridges can be customized based on specific industry requirements, ensuring accurate filtration of particles of varying sizes. The sintering process, which involves heating the metal powder and compacting it under pressure, can be adjusted to manipulate the porous structure of the filter. This allows control over the filtration accuracy, which can range from 1 to 300 microns. Consequently, industries can achieve high-quality filtration precision according to their specific operational needs, making these cartridges an adaptable and efficient choice across diverse applications.

Metal powder filter cartridges are typically fabricated from superior quality materials like stainless steel variants 304/316/316L/304L. These materials possess excellent corrosion resistance, making them highly resistant to acidic or alkaline environments. This resistance to corrosion allows the cartridges to maintain optimum functionality even in harsh chemical environments typical to industries such as the chemical processing, oil and gas, and wastewater treatment sectors.

Metal powder filter cartridges are typically fabricated from superior quality materials like stainless steel variants 304/316/316L/304L. These materials possess excellent corrosion resistance, making them highly resistant to acidic or alkaline environments. This resistance to corrosion allows the cartridges to maintain optimum functionality even in harsh chemical environments typical to industries such as the chemical processing, oil and gas, and wastewater treatment sectors.

Metal powder filter cartridges are crafted from materials like stainless steel that exhibit excellent corrosion resistance. Their inherent chemical stability facilitates their resistance against acidic or alkaline environments, mitigating the risk of material degradation and rust formation. Thus, they can maintain their mechanical strength and filtration performance even when exposed to harsh chemical environments, offering durable, reliable, and consistent filtration for various industrial applications.