What is HEPA filter?

HEPA (high-efficiency particulate air) filters, also known as high-efficiency particulate absorbing filters or high-efficiency particulate arrestance filters, adhere to stringent efficiency standards. To meet HEPA standards, these filters must remove at least 99.95% (per ISO and European standards) or 99.97% (per ASME and U.S. DOE standards) of particles with a diameter of 0.3 μm. They are highly effective at capturing a wide range of airborne contaminants, including pollen, dirt, dust, moisture, bacteria (ranging from 0.2 to 2.0 μm), viruses (ranging from 0.02 to 0.3 μm), and submicron liquid aerosols (ranging from 0.02 to 0.5 μm). Some microorganisms, such as Aspergillus niger, Penicillium citrinum, Staphylococcus epidermidis, and Bacillus subtilis, can be captured by HEPA filters equipped with photocatalytic oxidation (PCO). Additionally, HEPA filters can effectively capture floor dust containing bacteroidia, clostridia, and bacilli. Originally commercialized in the 1950s, the term "HEPA" has become both a registered trademark and a generic term for highly efficient filters. These filters find applications in various industries requiring contamination control, including manufacturing of hard disk drives, medical devices, semiconductors, nuclear facilities, food and pharmaceutical products. They are also commonly used in hospitals, homes, and vehicles.

What is the mechanism of HEPA filter?

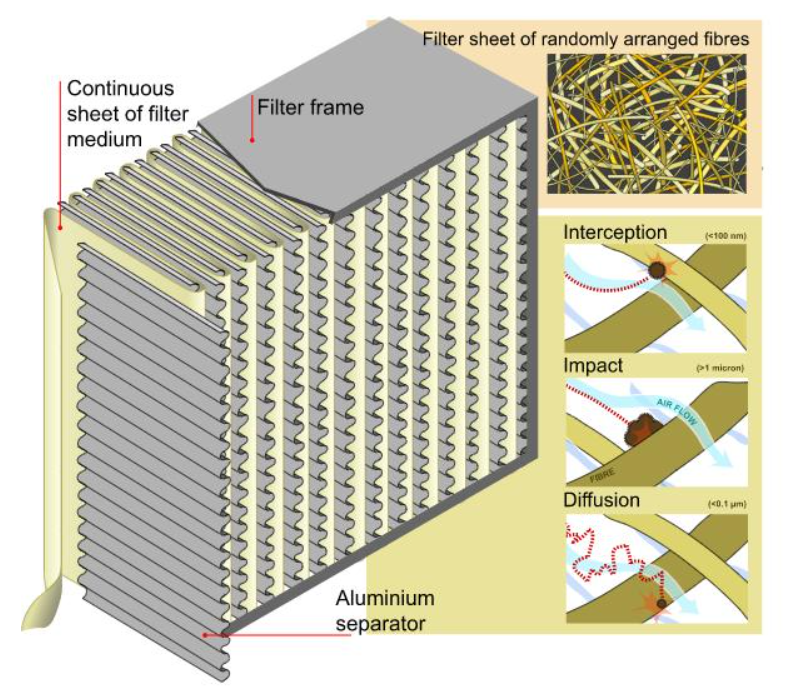

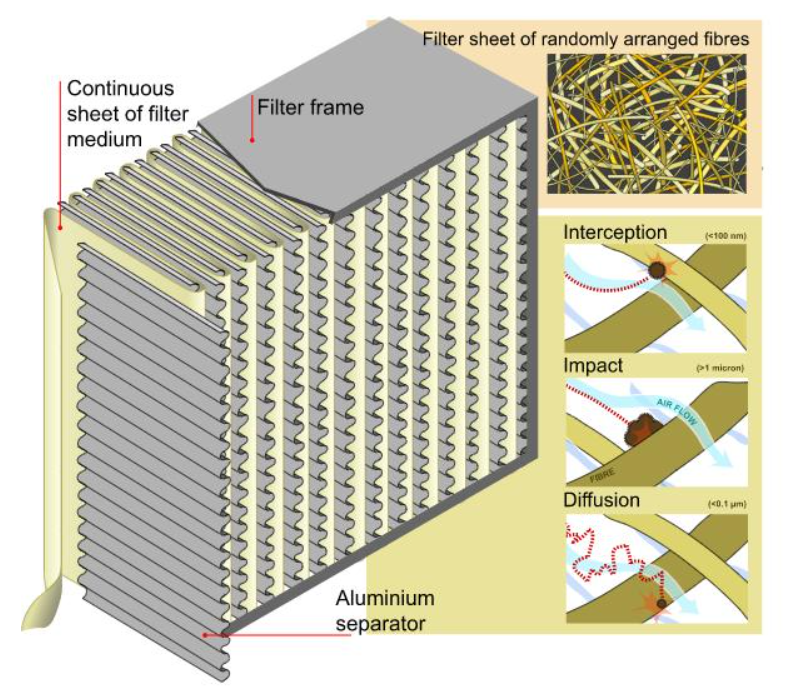

HEPA filters are composed of a mat of randomly arranged fibers.The fibers are typically composed of polypropylene or fiberglass with diameters between 0.5 and 2.0 micrometers. Most of the time, these filters are composed of tangled bundles of fine fibers. These fibers create a narrow convoluted pathway through which air passes. When the largest particles are passing through this pathway, the bundles of fibers behave like a kitchen sieve which physically blocks the particles from passing through. However, when smaller particles pass with the air, as the air twists and turns, the smaller particles cannot keep up with the motion of the air and thus they collide with the fibers. The smallest particles have very little inertia and they always move around the air molecules like they are bombarded by these molecules (Brownian motion). Because of their movement, they end up crashing into the fibers.Key factors affecting its functions are fiber diameter, filter thickness, and [[Face velocity is the measured air speed at an inlet or outlet of a heating ventilation and air conditioning (HVAC) system. ... Face velocity is measured in m/s and can be calculated as the volume flow rate (m3/s) divided by the face area (m2).. The air space between HEPA filter fibers is typically much greater than 0.3 μm. HEPA filters in very high level for smallest particulate matter. Unlike sieves or membrane filters, where particles smaller than openings or pores can pass through, HEPA filters are designed to target a range of particle sizes. These particles are trapped (they stick to a fiber) through a combination of the following three mechanisms:

Diffusion:particularly effective for particles smaller than 0.3 μm. This mechanism operates through the collision of the smallest particles, especially those below 0.1 μm in diameter, with gas molecules. As these tiny particles interact with gas molecules, they are redirected and propelled, colliding with the fibers of the filter media. This behavior closely resembles Brownian motion, significantly enhancing the likelihood of particle entrapment by either interception or impaction. Notably, diffusion becomes increasingly dominant at lower airflow rates, further optimizing the filtration efficiency of HEPA filters.

Interception:particularly effective for particles of intermediate size. As particles traverse the airflow in a straight line, they approach within one radius of a fiber and adhere to its surface. This process is particularly adept at capturing mid-sized particles that follow the path of the air stream. By intercepting particles along their trajectory, HEPA filters effectively trap a wide range of contaminants, contributing to their exceptional filtration performance.

Impaction:it is another crucial mechanism employed by HEPA filters to capture larger particles. When larger particles travel through the air stream, they are unable to maneuver around the curving contours and twists, leading them to collide directly with the fibers of the filter media. This effect is particularly pronounced when fiber separation is reduced and air flow velocity is increased, further enhancing the filter's efficiency in capturing larger contaminants. By exploiting the impaction mechanism, HEPA filters can effectively remove a wide range of particle sizes, ensuring clean and purified air output.

The HEPA filter boasts several distinctive characteristics that make it highly efficient in air purification:

Large Filtration Surface: Despite its lightweight design, the HEPA filter features a large filtration surface area. This expansive surface area allows for maximum exposure to air, enhancing its filtration capacity.

High Efficiency: HEPA filters are classified with efficiency ratings ranging from H10 to H14. This classification signifies the filter's ability to capture airborne particles, with higher ratings indicating greater efficiency in removing contaminants.

Low Resistance: Despite its high filtration efficiency, the HEPA filter maintains low resistance to airflow. This ensures that air can pass through the filter with minimal obstruction, promoting smooth operation and optimal air circulation.

Large Dust Holding Capacity: The filter possesses a significant dust holding capacity, allowing it to trap and retain a substantial amount of airborne particles. This capacity enables the filter to maintain effectiveness over extended periods without frequent replacement.

Comprehensive Particle Removal: HEPA filters excel in removing a wide range of airborne particles, including dust, pollen, mold spores, and other irritants. By effectively capturing these contaminants, the filter helps improve indoor air quality and creates a healthier environment for occupants.

The HEPA filter finds extensive applications across various industries and settings, including:

Food & Beverage: HEPA filters are crucial in maintaining sterile environments in food processing and packaging facilities, ensuring product safety and quality.

LCD Manufacturing: Cleanrooms in LCD manufacturing facilities utilize HEPA filters to remove contaminants and maintain pristine conditions essential for producing high-quality display screens.

Healthcare Industry: Hospitals and medical facilities rely on HEPA filters to maintain sterile conditions in operating rooms, isolation units, and cleanrooms, reducing the risk of airborne infections and ensuring patient safety.

Electronic: Electronic manufacturing facilities utilize HEPA filters to create controlled environments free from dust and particles, essential for the production of sensitive electronic components and devices.

Precision Instrument: Laboratories and research facilities employ HEPA filters to maintain clean environments for precision instruments, such as electron microscopes and spectrometers, preventing contamination and ensuring accurate results.

Chemical Industry: HEPA filters play a critical role in chemical manufacturing processes by removing airborne contaminants and maintaining clean air in production areas, vital for product quality and safety.

Working Temperature Limitation: It's important to note that HEPA filters are suitable for applications where the working temperature does not exceed 70°C, ensuring optimal performance and longevity of the filter in various operating conditions.