In the landscape of an industrialized world, efficiency and reliability are the pillars of any successful operation. One such element that bolsters these ideals is the humble yet sophisticated Air Compressor Filter Element. The component that warrants attention due to its notable benefits in the purification of compressed air for a range of applications.

Air compressor filter elements are the unsung heroes of many industrial processes. These elements take center stage in the proper functioning of various tools and machinery in a plethora of sectors, ranging from metallurgy, chemical industry, power, textile, automotive, aerospace and beyond. Their role cannot be overemphasized, as they screen out impurities from compressed air, proving instrumental in protecting equipment and enhancing their lifespan.

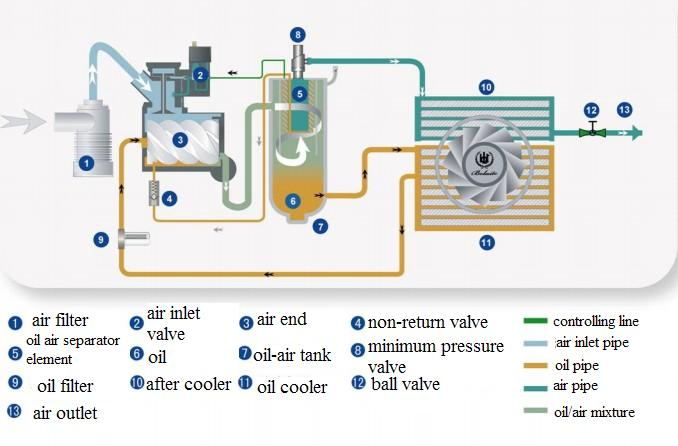

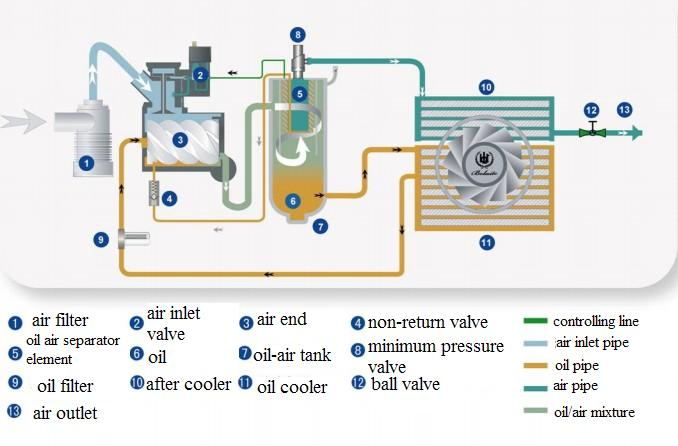

First, let's delve into the mechanics of the air compressor filter element. Their primary function is to process the oil-containing compressed air produced by the main engine. Post this, through a process of mechanical separation, the oil and gas in the compressed air are filtered out by the filter element. The tiny oil mist particles present therein are intercepted and agglomerated, forming oil droplets that concentrate at the filter's bottom. Through the oil return pipe, the oil droplets are channeled back into the compressor's lubrication system. This results in high-quality, pure discharged compressed air from the compressor, free of solid dust, oil, and gas particles along with other liquid substances.

In the assembly line, specific air compressor filter elements' utility can be witnessed. One such variant is the Oil Air Separator. Crafted with superfine glass fiber hailing from American manufacturing stalwarts HV and Lydall, the Oil Mist Separator performs the crucial task of capturing the oil-gas mist in compressed air completely. Its high-performance filtering ability ensures an air filtering accuracy of ≤10μm with efficiency peaking at 98%, cementing its importance in the assembly line.

Another noteworthy filter element is the lubrication oil filter. Made with superfine glass fiber of HV Company in America or wood pulp filter paper of Ahlstrom Company in Korea, this variant specializes in capturing suspended particles and oil residue in the lubrication oil, thereby protecting the host machine. Boasting a substantial filtering accuracy of 5~15μm and an impressive filtering efficiency of 99.8%, the lubrication oil filter proves to be a critical element in industrial operations.

Furthermore, a closer look at the air compressor filter element reveals an impressive service life of about 2000 hours. Such longevity contributes to the cost-efficiency of these components, adding another feather to their cap. However, just like any other machinery element, they do require regular replacements to maintain their function at optimum levels.

The sheer versatility of the air compressor filter elements is commendable as they find their usage in a vast array of industries like steel, shipbuilding, electronics, petroleum, mining, light industry machinery manufacturing, paper printing, transportation facilities, and the list continues.

In a world where the drive to find better and efficient ways of carrying out industrial activities is a cause célèbre, the importance of air compressor filter elements is going from strength to strength. Therefore, the understanding of these seemingly simple yet incredibly effective components becomes an essential part of the process to continue pushing the bars of productivity even higher.

After all, the strength of a chain is determined by its weakest link - and rest assured, with the right air compressor filter elements in your arsenal, weakness is a term that will find no room in your operations. The future looks bright for industries adopting these tools in their daily operations, moving towards an era of cleaner, safer, and more efficient production capabilities.

The primary contrast between an air filter and a lubrication oil filter lies in their specific purposes within a system.

An air filter is primarily designed to purify the air that enters into a system. It works by removing airborne particulates like dust, pollen, and microbes. For air compressor systems, the filter elements are often made from wood pulp filter compounds, like those from HV and Ahlstrom Companies. The focus here is to provide a high filtering accuracy that efficiently gets rid of impurities like suspended particles, sand, water, and oil-gas mist present in air.

On the other hand, a lubricating oil filter functions to keep the oil feeding your engine clean. The main function of this filter is to sieve out any contaminants like metal fragments and dust that might have found their way into the oil and could potentially damage the engine. The material of a lubrication oil filter element is often made from superfine glass fiber or wood pulp filter paper, providing an exceptional filtering accuracy that swiftly removes impurities such as suspended particles and oil residue.

In essence, while both air filters and oil filters operate to keep a system running smoothly by removing contaminants, the key difference lies in the medium they are designed to purify; air filters handle air, while oil filters handle oil. Also, these two filter types can often differ in design, size, and location, depending upon the specific requirements of the system wherein they are employed.

Air filters need to remove suspended particles, sand, and moisture from the air for several reasons.

Firstly, these impurities, if left unchecked, can cause extensive damage to the components of the air compressor system. Suspended particles and sand, for instance, can cause abrasive wear, leading to inefficiencies and breakdowns over time. Water is particularly problematic because when it condenses, it forms droplets that can potentially lead to rusting and corrosion within the system.

Secondly, these contaminants can also drastically affect the quality of the end products in industries like food processing, pharmaceutical manufacturing, or spraying casting where clean, dry air is a prerequisite.

As for lubrication oil filters, they function to maintain engine cleanliness by continually filtering out impurities from the circulating oil. The primary material of the lubrication oil filter is either made of superfine glass fiber or wood pulp filter paper, which are highly capable of trapping impurities such as suspended particles and oil residues.

It works in a straightforward yet efficient manner. When the oil circulates through the engine, it collects particles of dust and minute metal fragments that come from the engine components' wear and tear. This contaminated oil then moves through the oil filter where the impurities are captured.

By removing these particulates, the lubrication oil filter ensures the oil feeding the engine remains clean, reducing the potential for abrasive wear and damage to the engine parts, subsequently prolonging the life of the engine.