In the demanding world of industrial production, implementing a reliable and efficient filtration system is crucial for maintaining quality control and uninterrupted operation. The Duplex Filter, an innovative and industrial-grade filtration device, proudly steps into this crucial role, revolutionizing how we understand filtration and separation processes.

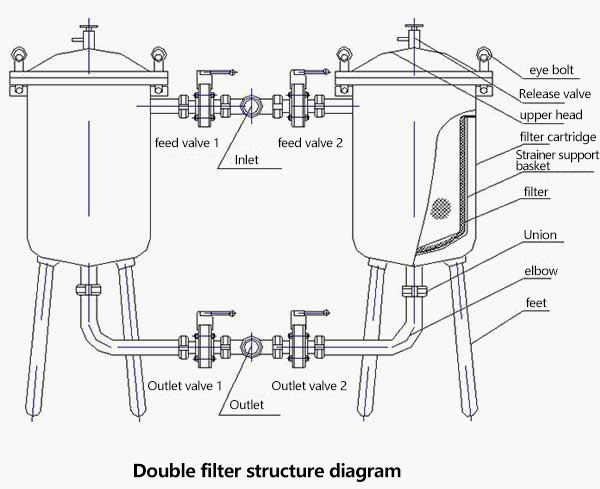

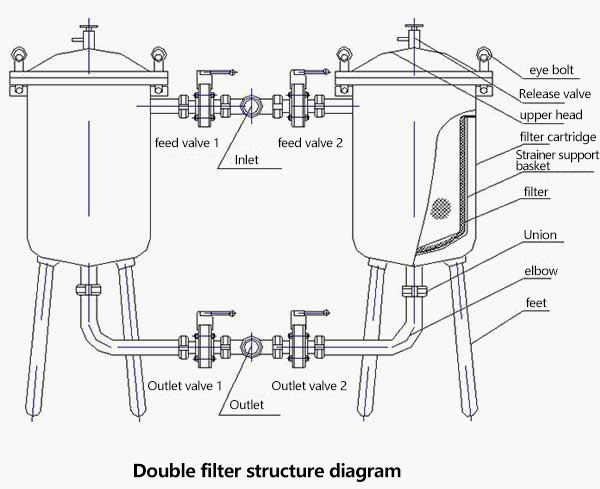

The Duplex Filter stands out for its unique design and superior operational performance. Comprising two stainless steel filters in parallel, it is sometimes referred to as a double-switch filter. It consistently ensures filtration accuracy without interruption, a claim substantiated by its novel and solid construction, excellent sealing performance, and robust flow capabilities.

What sets the Duplex Filter apart is its focus on continuous work, explicitly designed to cater to the need for non-stop industrial operations. Its structure ensures that whenever one filter element is blocked and requires replacement, operations don't need to cease. A simple switch to the other filter via the three-way full-diameter ball valve allows the continuation of the filtration process. Then, the blocked element can be replaced without stopping the work of the main machine. This ability significantly reduces downtime, optimizes operation, and subsequently lowers operating costs.

The Duplex Filter finds extensive applications in various industrial sectors. It can filter hydraulic oil, lubricating oil, and other substances needed by an industrial quenching oil cooling system. It also plays a pivotal role in RO security filtration, seawater desalination pretreatment, and filtration of low-temperature materials in refrigeration.

This highly versatile device is adept at filtering water suspended solids, particulate matter, water fouling, bacteria and algae, rust, and more to ensure purity and quality control. Its unique ability to work with a broad range of substances and applications is complemented by its uncomplicated structure and easy operation.

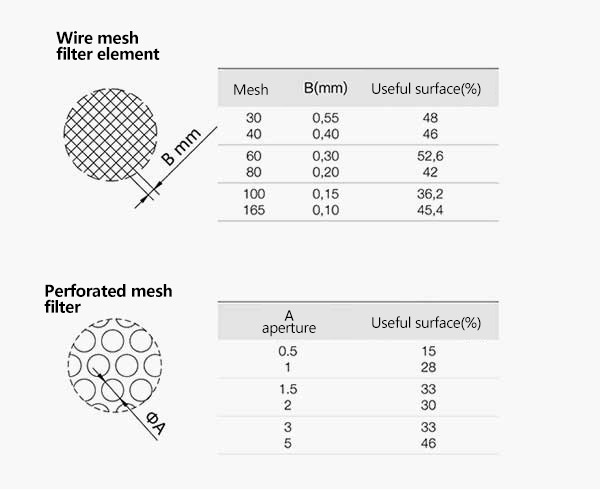

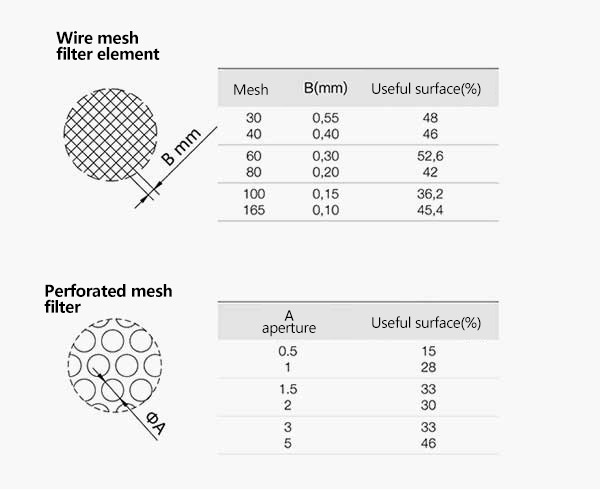

In terms of structure, the Duplex Filter includes a metal mesh basket to support the cartridge or filter bag. The liquid enters the filter, is purified by the cartridge, and then exits from the outlet, while the impurities are efficiently caught by the cartridge.

Constructed from durable, high-quality materials, each Duplex Filter guarantees long-term stability and efficiency. The device's shell is made from carbon steel or stainless steel with a flange pressure ranging from 0.25-6.3MPa/150-300LB. The filter element is also made of stainless steel, providing reliability and durability even in demanding conditions.

In conclusion, the Duplex Filter exemplifies progress in industrial mechanism, proving to be a revolutionizing tool in the filtration process. Its consistent performance, simplicity of use, low maintenance costs, and excellent material selection make it an optimum choice for any industrial setup requiring a stellar filtration solution. The Duplex Filter's unique ability to adapt to various operational requirements makes it a reliable partner for industry players, always aiding to keep their operations efficient and unimpeded.

The Duplex Filter incorporates a unique design feature that allows for continuous operation without interruption, even during the filter replacement process - all thanks to its dual filter configuration and the full-diameter three-way ball valve.

Here's how it works:

The Duplex Filter is made up of two single cartridge filters operating in parallel. While one filter is actively involved in the filtration process, the other serves as a standby. Whenever the active filter cartridge becomes blocked or reaches its saturation point where it needs to be cleaned or replaced, there is no need to halt the entire filtration process.

At this point, the three-way ball valve positioned between the two filters is crucial. By simply switching this valve, the filtration process is instantaneously transferred to the second, standby filter. This ensures that the filtration operation remains uninterrupted, and the previously active, now clogged filter can be cleaned or changed without halting the operation of the main machine.

In short, this innovative mechanism of the Duplex Filter allows for continuous "non-stop" work, ensures large filter area, reduces downtime, and significantly boosts productivity and efficiency in any industrial operation.

Absolutely, that is one of the main advantages of the Duplex Filter. When one of the filter cartridges becomes clogged or needs replacement, you can seamlessly switch the operation to the second, standby filter by simply turning the three-way ball valve. This ensures the continuation of the filtration process and the operation of the main machine.

With the filtration process now shifted to the standby filter, the initially active but now clogged filter is not in use. This gives you the opportunity to clean or replace the clogged filter cartridge without interrupting the operation of the main machine.

Once the maintenance is finished, the cleaned or replaced filter can serve as the standby, ready to take over when the active filter next requires maintenance. This innovative design allows the Duplex Filter to maintain a continuous, unimpeded work flow, a major advantage in industrial settings where prolonged downtime can be costly.

The significant advantage of using the standby filter during the cleaning or replacement process of the clogged filter cartridge lies in its ability to ensure uninterrupted operation and productivity.

In many industrial processes, halting operations for filter cleaning or replacement can lead to downtime and slow down productivity. Here is where the Duplex Filter, with its dual filter design and standby feature, truly shines; it eliminates the need for operational downtime commonly associated with filter maintenance.

While one of the filters in the Duplex Filter system is being serviced, the other filter continues to function seamlessly, filtering materials and maintaining a steady operation. As a result, continuous work can be maintained without causing interruption or delay in the industrial processes.

Furthermore, this feature saves operators the worry of having to halt their processes, leading to a streamlined operation, better time management, and consequently, increased overall productivity. In short, the standby filter ensures continuous operation, reduces the cost related to stops, and improves efficiency in the workflow.