The application of multi-column self-cleaning filter as the front stage of reverse osmosis can increasingly bring into play its advantages. Let us learn the detailed information together.

In ordinary water treatment systems, reverse osmosis devices are key components that separate water into pure water and wastewater. However, micro-pollutants such as suspended particles, bacteria, and algae in the water may corrode the reverse osmosis membrane elements, causing their performance to decline. Therefore, we need a pretreatment equipment that can effectively remove these pollutants and operate stably under a wide range of working conditions. This is a multi-column self-cleaning filter. It works as follows:

Water inlet: Untreated water first enters the filter, passes through the coarse filter screen to remove larger particulate matter, and then flows into each filter column.

Filtration process: After the water flow enters the filter column, the particulate matter is intercepted by the fine filter, and the clean water flows out through the filter. Due to the multi-column design, even if one filter column is being backwashed, other filter columns can continue to filter to ensure the continuity of the filtration work.

Backwash: The impurities on the filter continue to increase as the filter becomes clogged. When the pressure difference reaches the set value or the operating time reaches the set value, the control system will automatically open the backwash valve, and the backwash pump will start working and perform backwash independently. Rinse to remove impurities on the filter. The backwash process is often carried out with the filter's own water, saving resources.

Refiltration after backwashing: After backwashing is completed, the filter column automatically switches back to the filtration state and starts the next round of filtration. Because the filter is self-cleaning, it has a long service life, effectively providing a stable, pure water source for the reverse osmosis system.

Scope of application: Due to its self-cleaning properties, this system is suitable for many industries such as electric power, reverse osmosis front stage, petrochemicals, fine chemicals, food and beverages, automobile industry, metallurgy, papermaking, medicine, microelectronics, environmentally friendly water treatment, etc.

Multi-column self-cleaning filters are also called multi-column backwash filters, and their working principle is very unique and effective. Here are each stage it goes through in filtering water:

Liquid enters the filter: First, the filtered liquid enters the filter from the inlet. At this time, the liquid first passes through the lower fixed plate and enters the filter screen. The filter screen is mainly composed of multi-layer metal braided mesh or wedge-shaped mesh, and its purpose is to filter out impurities in the liquid.

Filtration process: After the liquid enters the filter, it will flow from the inside of the filter to the outside. In this process, the filter will directly intercept suspended solids, particles and other impurities in the water. After being filtered by the filter, the clean water will flow out of the filter from the outlet of the filter cartridge.

Backwash the filter column: The driving device drives the cleaning arm to rotate so that the cleaning arm suction nozzle corresponds to the lower port of the filter column one by one. The impact of negative pressure water flow is used to clean the impurities in the filter column, and then the impurities are eliminated through the drain valve. .

At the end of backwashing: When impurities in the filter accumulate on the inner surface of the filter element, causing the inlet and outlet pressure difference to increase to the set value, or when the filter element is automatically cleaned through timing control, backwashing will end. The filtration process can then be continued in the current column.

Through this working principle, the multi-column self-cleaning filter can effectively intercept and remove suspended solids, particulate matter and other impurities in the water, thereby reducing the turbidity of the water, improving the water quality, and reducing the generation of dirt, bacteria, algae, rust, etc. in the system, so as to Achieve the effect of purifying water quality. Moreover, due to the multi-column design, even if one column is backwashing, other columns can continue to filter, thus ensuring the continuity and stability of water treatment.

The advantages of multi-column self-cleaning filters will be explained in more detail below:

Superior cleaning effect: The multi-column self-cleaning filter has a unique backwash function, which can efficiently remove particles and impurities attached to the filter. More importantly, this cleaning process will not affect the normal filtration work, because cleaning and filtration can be carried out at the same time, which ensures that the cleaning process is efficient and thorough.

Large processing flow: One of the main advantages of the multi-column self-cleaning filter is its high processing capacity because it has multiple independently operating filter columns. These multiple filter columns can work at the same time to provide a large filter area, so the treatment flow is large, which can better meet the needs of large water treatment systems.

High filtration precision: According to needs, you can choose suitable filter structure and materials. Therefore, the multi-column self-cleaning filter can achieve high filtration precision and can effectively filter impurities from large particles to tiny particles.

High economy: Since the multi-column self-cleaning filter has the characteristics of automatic backwashing and cleaning, the labor and material costs in maintenance and cleaning are greatly reduced, and the operating cost is low.

Continuous water supply: During each backwash, the corresponding filter column and filter screen are cleaned, and other filters can still continue to filter. This design ensures that when the filter is cleaned, the system's water supply always maintains continuity and stability and will not be interrupted by cleaning.

Wide range of applications: Multi-column self-cleaning filters are suitable for various industries that require high-quality water sources, such as electric power, chemical industry, food, beverage, automobile, metallurgy, papermaking, medicine, microelectronics and other industries. Especially in industries with extremely high water quality requirements, such as petrochemicals and microelectronics, it has demonstrated its significant performance advantages.

In summary, the intelligent design of the multi-column self-cleaning filter not only effectively filters the water flow, but also ensures the continuous operation of the system. More importantly, it provides higher filtration precision and greatly enhances the effect of water purification. Moreover, its wide range of applications also makes it the first choice filtration equipment in many industries.

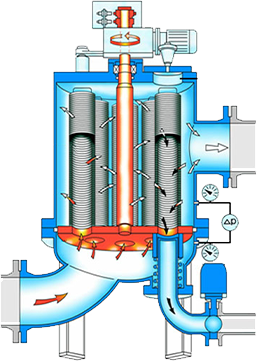

Explain the structure of the multi-column self-cleaning filter in detail:

Tank body: The tank body is usually made of pressure-resistant and corrosion-resistant materials. It is the outer shell of the filter. Its main function is to protect the internal filter elements and mechanisms from the impact of the external environment, while withstanding the pressure during operation.

Filter column: The filter column is the core part of the multi-column self-cleaning filter. It is usually composed of multiple filter columns arranged in parallel. Each filter column has an independent inlet and outlet. The filter column is generally made of corrosion-resistant and high-strength materials such as stainless steel. It is equipped with a microporous filter inside to filter out impurities in the passing water flow.

Backwash structure: The backwash structure is mainly used for backwashing when the filter needs to be cleaned. This structure can generate a powerful reverse flow of water to wash away the impurities attached to the filter, further ensuring the filtration effect.

Reducer: The reducer is the driving part of the filter. It can drive the backwash device to rotate, ensuring that the cleaning process can evenly cover all filter columns, ensuring the comprehensiveness and effectiveness of cleaning.

Electric valve: The electric valve in the system is used to control the flow of water. When backwashing begins, the cleaning water can be directed to the backwashing device by opening a specific electric valve.

Differential pressure controller: Multi-column self-cleaning filters are usually equipped with a differential pressure controller. When the pressure difference between the inside and outside of the system reaches a certain level, the differential pressure controller can start the backwash process to prevent the decrease in filtration efficiency caused by filter blockage. .

Electric control box: The electric control box controls the entire backwash and self-cleaning process, including starting cleaning when the pressure difference reaches the set range, controlling the operation and suspension of the backwash device, and the opening and closing of the electric valve.

These components together form a multi-column self-cleaning filter, which enables the filter to automatically adjust its working status according to specific water quality conditions to achieve the best filtration effect.

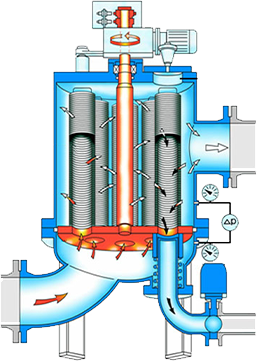

Backwashing means that the system cleans the filter screen through reverse flow of water. In a self-cleaning filter, the backwash structure works as follows:

Sensing impurity deposits: A differential pressure controller in the filter monitors the pressure difference on both sides of the filter. When there are too many impurities attached to the filter, causing the pressure difference to exceed the preset value, backwashing will be triggered.

Start backwashing: Once the backwash signal is received, the electric control box will control the electric valve to switch to the backwash state and drive the backwash device to start working.

Backwash process: The backwash device will generate a strong flow of water in the opposite direction along the outer surface of the filter. This flow is like a brush, brushing off the impurities attached to the surface of the filter bit by bit. At the same time, these impurities will be brought out of the filter with the backwash water.

Ending backwashing: Backwashing is usually performed in a spiral shape with the column axis as the center. After every part of the filter has been cleaned, backwashing is complete. At this time, the electric control box will control the electric valve to switch back to the normal filtration state, and control the backwash device to stop.

In this way, the filter can operate continuously and stably to ensure clean water quality.

It should be noted that the water used in the backwash process cannot usually be used directly and needs to be discharged to a designated place or undergo subsequent treatment before it can be used again.

The electric valve is an important control component. In order to realize the backwash function, the electric valve will switch to the backwash state. The following is the main switching process:

Differential pressure sensing: The differential pressure controller inside the filter equipment monitors the pressure difference on both sides of the filter. When the impurities on the filter accumulate to a certain extent, causing the pressure difference to reach a preset threshold, the control system of the filter equipment will start the backwash process.

Send switching command: After the backwash process is started, the control system will send a command to the electric actuator of the electric valve to switch to backwash mode.

Actuator work: The electric actuator is the core component of the electric valve. After receiving the instruction, it will drive the valve to rotate to the corresponding position to open or close the valve. The actuator usually works by receiving a standard DC signal and then outputting the corresponding rotational angular displacement based on this signal.

Valve switching: Driven by the actuator, the valve will rotate to the designated position to switch to backwash mode. The exact angle of rotation depends on the valve design and backwash requirements.

Backwashing starts: After the valve switches to backwashing mode, the control system will confirm the valve status, start the backwashing device for cleaning, and start the backwashing process.

It should be noted that switching the electric valve to backwash mode not only involves the rotation of the valve itself, but may also involve the work of other components in the system, such as closing the main water supply, opening the sewage channel, etc. All these steps together achieve the reverse flushing mode. Initiation of flushing mode.

After the process is completed, the valve needs to return to the normal filtration mode in a similar manner, mainly the control system sends a reset command and the actuator drives the valve to rotate to the normal filtration position. This switching mechanism ensures that the equipment can quickly and accurately backwash when needed, maintaining good filtration effects and long-term stable operation.

The multi-column self-cleaning filter is suitable for environments with poor working conditions and high impurity content. Its solid content generally does not exceed 300ppm. In such situations, the filter element needs to be replaced frequently.

For occasions requiring relatively high precision (10~30 microns) and relatively small processing capacity (≤100m3/h), or situations requiring relatively large processing capacity (≥3000m3/h) and relatively coarse precision (≥3mm), you can choose multiple Column self-cleaning filter.

In addition, the following industries also frequently use multi-column self-cleaning filters:

Power Industry

Reverse osmosis pre-treatment

Petrochemical industry

Fine chemical industry

Food and Beverage Industry

auto industry

Metallurgical industry

Paper industry

Pharmaceutical industry

Microelectronics industry

Environmental protection water treatment industry

In other words, a simple summary is that multi-column self-cleaning filters are suitable for various industrial environments with high impurity content, large flow rates, and high filtration precision, and ensure that the heat exchanger of the cooling water system is always in a good working environment. Excellent performance in reducing the breakdown of the entire system caused by impurities in circulating cooling water.