A hydraulic oil filter is a crucial component of any hydraulic system, as clean oil is necessary for optimal system performance and longevity. Here's a more detailed explanation of how hydraulic oil filters work:

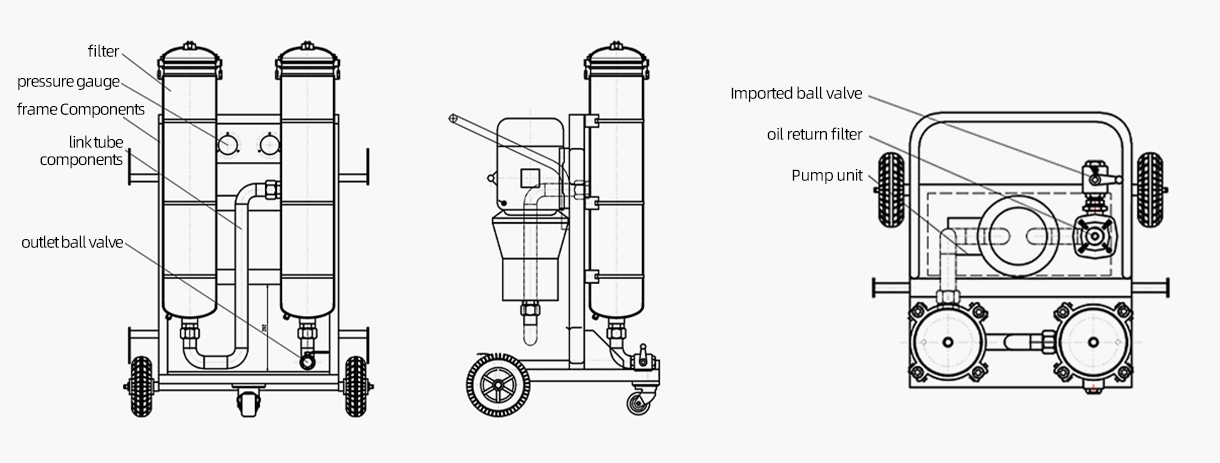

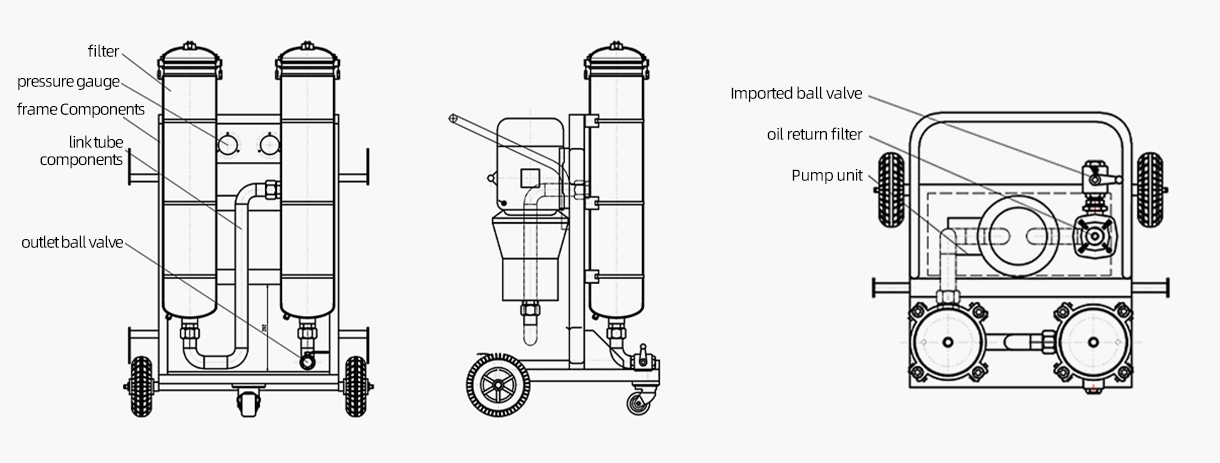

Oil Entry: The hydraulic system pumps oil into the filter through an inlet port. This oil is usually under high pressure, which aids the flow through the filtration pathway.

Pre-filtration: Upstream of the main filtration medium, there may be a pre-filtration barrier made from a coarse material. This is designed to intercept large-sized contaminants that may otherwise clog the finer main filter prematurely.

Primary Filtration: The oil then flows into the primary filtration section, typically made up of a folded or pleated synthetic or cellulose fiber medium that increases the available filter surface area. As oil is forced through this medium, particles larger than a preset size (measured in microns) are trapped on the surface or within the media's fibers due to various filtration mechanisms, such as direct impaction, sieving, interception, and diffusion.

Secondary Filtration: In some high-end filters, after the primary filtration, there may be a further 'polishing' stage. Here, another layer of filtration media catches any ultra-fine particles missed in the primary stage.

Bypass Valve: If the filter becomes too clogged with contaminants that it restricts the oil flow, a bypass valve will open. This mechanism ensures the continued operation of the hydraulic system, even if the oil isn't filtered. While this allows the system to function, it isn't ideal long-term as unfiltered oil can harm system components. Therefore, it's vital to monitor filter health and replace it before this valve needs to open.

Oil Exit: Finally, the purified oil exits via an outlet port and is circulated back into the hydraulic system. The filtered oil reduces wear on system components and contributes to system efficiency and machinery lifespan.

Contamination Indicator (optional): Modern hydraulic filters may include a contamination indicator. This visual or electronic component communicates when the filter element is blocked and requires cleaning or replacing.

In short, a hydraulic oil filter ensures that the oil circulating within a system is clean and free of damaging debris. To ensure a hydraulic system's efficient and problem-free operation, you need to perform regular filter maintenance, promptly replacing the filter as per the system's specifications or when indicated.