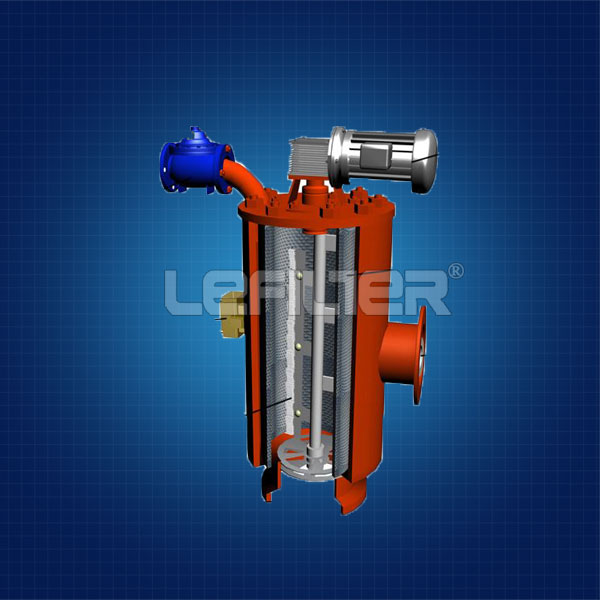

Self-cleaning filter - Filter for the water treatment section of the circulating water in steel mills

Introduction:Self-cleaning filter with filtration accuracy from 50 to 5000 microns can be selected, with large filtration area and high dirt-holding capacity, which can be customized by users according to actual working conditions. The cleaning method is simple, and the cleaning cycle is monitored to realize automatic cleaning and discharging, and all parameters in the automatic filter control system can be adjusted. It is equipped with motor overload protection, which can effectively protect the motor.

We're here to help:

Easy ways to get the answers you need.

Product parameter:

Automatic backwash filter is a kind of self-cleaning filter that consists of multiple stainless steel filer elements and can continuously perform filtration for 24 hours.

Automatic online continuous filtration, continuous filtration during backwashing to reduce downtime and maintenance costs.

The control system can be tailored to monitor pressure and time settings for various fluids.

Gap type high performance filter is adopted, which features high precision, large effective filter area, small pressure drop and high backwash efficiency.

Compact design ensures that installation requires minimal space and is easy to install. The inlet and outlet ports are adjustable according to end users' requirements.

Filter rating 50–2000 μm, suitable for the filtration of all kinds of raw water, cooling water, process water and low viscosity fluids with a viscosity of less than 40 mPa.s and impurity content less than 300 ppm

Automatic backwash filer can effectively filter out solid particle contaminants from water and low viscosity liquids (such as rolling emulsion, etc.), so that the liquid cleanliness can meet the system operation and downstream process requirements and protect the downstream key equipment. As a result, automatic backwash filers are widely used in the following industries.

Oil & gas. Injection well water filtration; act as a pre-filter for hydrocracking, hydrogenation modification, hydrorefining and hydrodesulfurization reactor to prevent the catalyst bed from clogging;

Metallurgy. Rolling mill coolant filtration;

Marine filtration system. Seawater desalination filtration; ballast water filtration;

Water treatment. Boiler supply water filtration;

Pulp & paper. Starch slurry filtration; paper making water filtration.

Please fill in your procurement needs and contact information