Filtration media:

Any porous material that allows liquid to pass through a solid-liquid interface while retaining solid particles, achieving solid-liquid separation, is called a filter medium. The performance of a filter medium directly impacts the filtration and separation capacity and precision of the process. Therefore, filter media plays a crucial role in the filtration and separation process and is often referred to as the "heart" of filtration and separation equipment. With the continuous advancement of filtration technology, the variety of filter media has steadily increased.

Based on the material used, filter media can be categorized as cotton, wool, synthetic, glass, ceramic, and metal.

Based on the structure, filter media can be divided into flexible, rigid, and loose types. Flexible media include metal filter media, non-metallic filter media (cotton fabric, wool fabric, silk fabric, synthetic fiber fabric), glass fiber fabric, non-woven fiber fabric (non-woven filter cloth, filter paper, filter felt, filter pad), metal and non-metal mixed media, etc.; rigid media include sintered metal mesh, metal fiber sintered felt, powder sintered material, porous ceramics, sintered porous plastics, sintered aluminum oxide, glass filter media, etc.; loose media include diatomaceous earth, expanded perlite powder, cellulose, sand, charcoal powder and anthracite, etc.

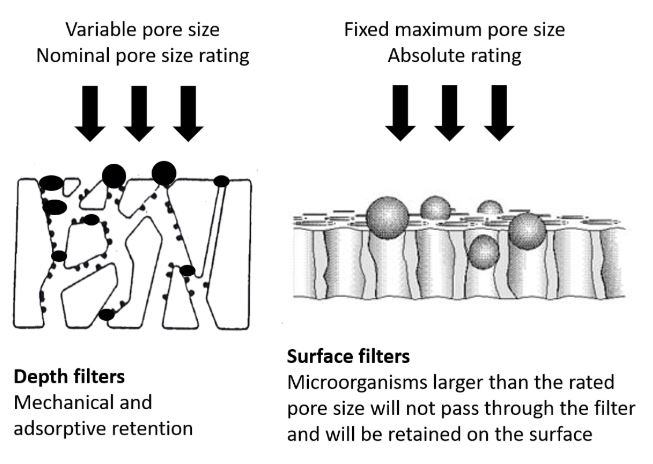

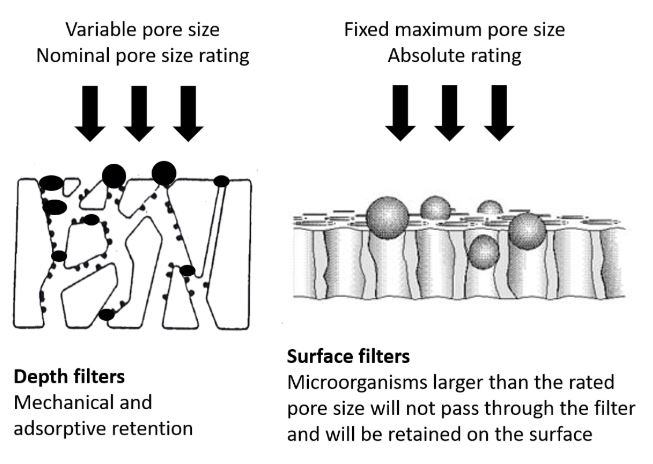

Surface filtration:

This type of filter media acts as a surface to intercept dirt during operation, purifying and separating the working medium. Because dirt particles accumulate on a geometric plane upstream of the surface, they are easily clogged by dirt, losing their filtering capacity. Therefore, their dirt holding capacity is generally low, requiring frequent cleaning or replacement. Woven porous mesh and generally wire mesh are typical examples of surface-type filter media.

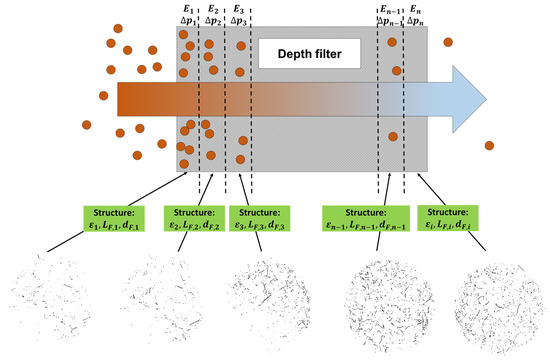

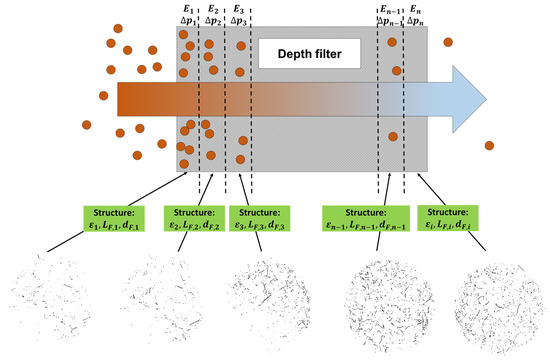

Depth filtration:

It is generally made of permeable material with numerous semi-through and through-holes. Its filtering action occurs throughout its entire thickness. Some dirt particles are blocked on the surface immediately upstream of the medium, while smaller particles enter the filter medium and are adsorbed on the pore walls due to contraction, expansion, and hydraulic effects, or are deposited and removed due to bridging or changes in fluid direction. Therefore, depth-type filter media has a larger dirt holding capacity, better filtration performance, and a longer lifespan than surface-type filter media, but suffers from relatively poor cleaning performance.