Executive Summary

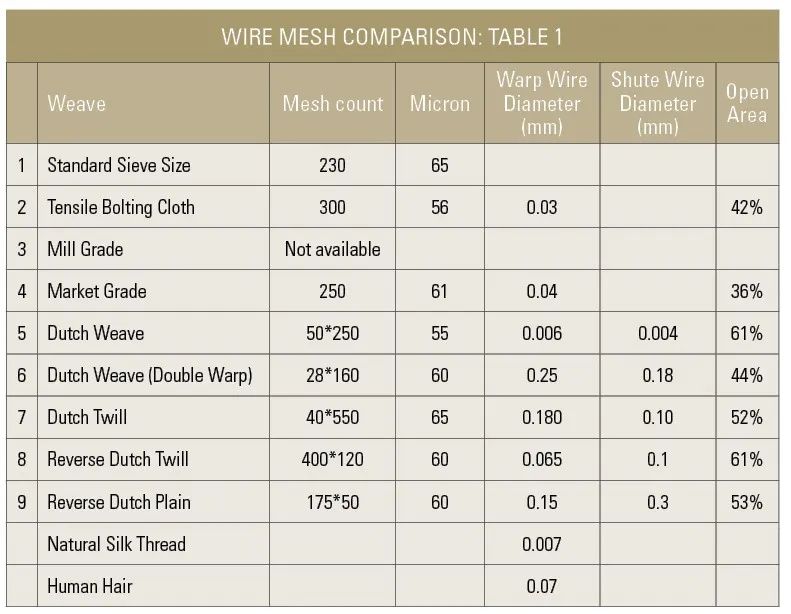

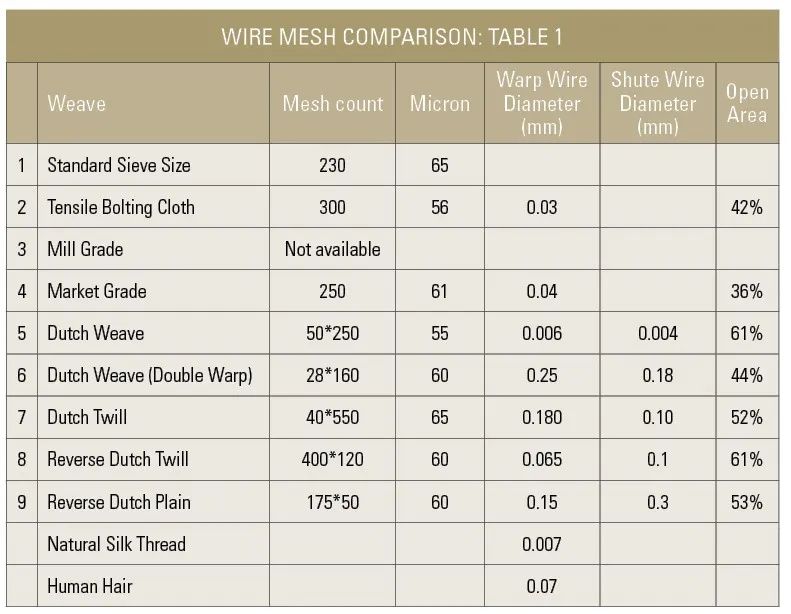

Selecting wire mesh for filtration involves far more than micron ratings. This article examines critical durability, manufacturability, and operational factors through a 60-micron case study. We compare nine mesh weaves, analyze failure modes under pressure cycling, and provide guidelines for balancing performance with production realities.

The Micron Rating Fallacy

While 60-micron retention is a common specification target, nine distinct weave types meet this requirement with dramatically different characteristics:

| Weave Type | Relative Strength | Open Area % | Filtration Efficiency |

|---|

| Plain/Square | Low | High | Standard |

| Twilled | Medium | Medium | Improved |

| Dutch Plain Weave | High | Low | Excellent |

| Dutch Twill Weave | Very High | Very Low | Superior |

| 5 Specialty Weaves | Variable | Variable | Application-Specific |

The Durability Tradeoff Matrix

Four critical pressure-related failure modes dictate mesh selection:

| Failure Mode | Cause | Prevention Strategy |

|---|

| Burst Failure | ΔP > Burst Pressure | Overspecify burst strength by 50% |

| Bypass Leakage | ΔP > Valve Setting | Install dual safety valves |

| Work-Hardening Fractures | Pressure Cycling | Avoid unsupported spans |

| Edge Degradation | Cleaning/Handling Damage | Reinforce perimeter welds |

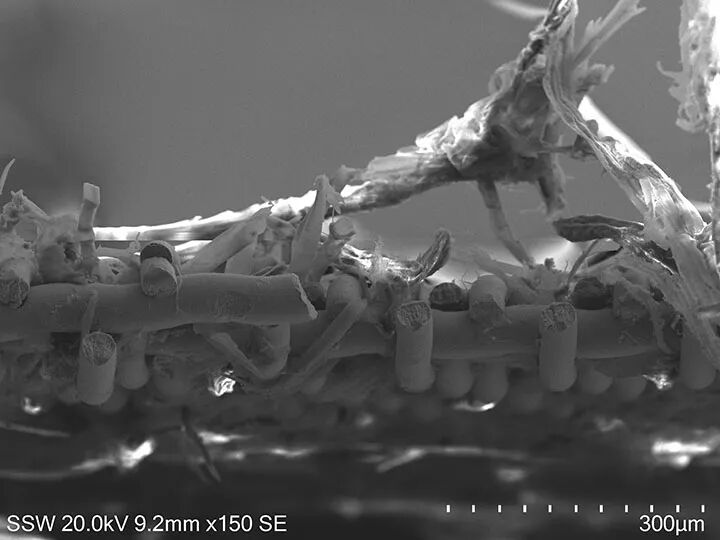

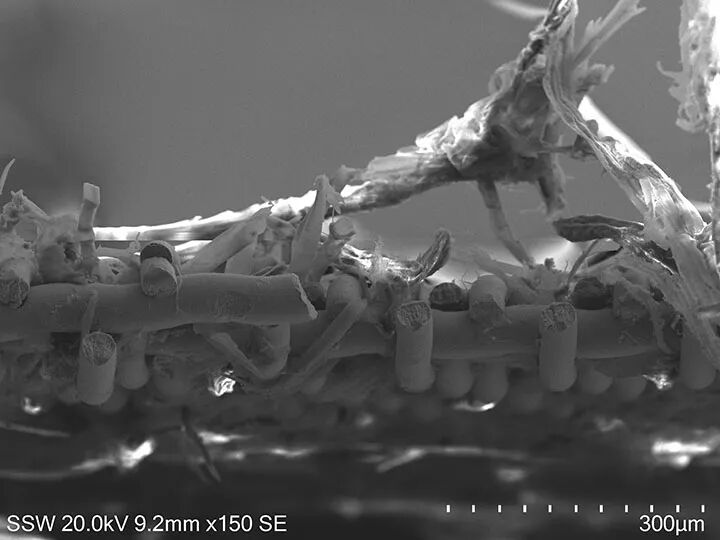

Critical Failure Mechanisms:

1.

Pressure Cycling Damage:

2.Handling Degradation:

•78% of premature failures originate during cleaning

•Edge reinforcement reduces replacement frequency by 40%

Manufacturability Constraints

Converting mesh into functional filters introduces production challenges:

Forming Limitations

| Process | Compatible Weaves | Risk Factors |

|---|

| Pleating | Plain/Twilled Only | Dutch weaves crack at bends |

| Welding | >80μm Wire Diameter | Thin meshes melt through |

| Sintering | Monolayer Only | Laminates delaminate |

| Crimping | All Types | Open area distortion >15% |

Industry Best Practices1.Design Philosophy Shift

2.Manufacturing Partnerships

3.Supply Chain Strategy