A port container site needs to process a large amount of oily wastewater every day, mainly oily wastewater generated after flushing or maintenance of various construction machinery. The treated effluent water quality meets the comprehensive sewage discharge standards and is discharged into the municipal sewage pipe network, and then enters the sewage treatment plant for treatment.

The equipment occupies a small area and has low investment. The walnut shell filter can filter out grease in sewage, and the oil content after filtering is ≤5mg/L.

When the equipment is backwashed, the agitator turns over the filter material, and the water flows from bottom to top, so that the filter material can be cleaned before use.

This equipment has strong adsorption capacity, large pollution interception capacity, oil immersion resistance, strong pressure resistance and stable chemical properties.

Specially processed walnut shells are used as the filter material. The filter material can be backwashed and reused. It can be directly backwashed with pre-filter water without the need for air sources and chemicals.

This filter is a separation equipment successfully developed based on the principle of filtration and separation. It uses oil-resistant filter material-special walnut shell as the filter medium. It uses the characteristics of large specific surface area, strong adsorption force and large dirt interception capacity of walnut shell to remove oil and Suspended matter.

When filtering, the water flows from top to bottom, passing through the water distributor, filter material layer, and water collector to complete filtration. During backwashing, the agitator turns over the filter material, and the water flows from bottom to top, so that the filter material is thoroughly cleaned and regenerated.

Working environment parameters

Working pressure: ≤0.6MPa

Inlet water pressure: ≥0.4MPa

Backwash water pressure: ≥0.15 MPa

Pressure difference between inlet and outlet: 0.1-0.2MPa

Working method: pressure type

Operation mode: water flow from top to bottom

Filtration speed: 20-25m/h

Operation cycle: 8-24h

Backwashing method: water backwashing

Backwash water consumption: 1-3%

Backwash intensity: 4-15l/s·m2

Backwash duration: 20-30min

Backwash expansion rate: 30-50%

Due to the hydrophilic but not lipophilic nature, stirring is used during backwashing to cause the walnut shells to rub against each other during movement, resulting in strong desorption ability, strong regeneration ability, and good chemical stability, which is conducive to long-term stable filter performance. The equipment adopts deep bed filtration, which can greatly improve the interception capacity.

The patented technology anti-clogging labyrinth is used to replace ordinary water distribution screens, which avoids clogging that may occur with the increase in operation time or changes in water quality during the operation of the filter. It has the characteristics of strong adsorption, large amount of dirt interception, resistance to oil immersion, double-effect removal of oil and suspended solids, easy regeneration, backwashing without adding chemicals, and can be connected in series or parallel.

Onshore and offshore oil fields, petrochemical and metallurgical oily wastewater treatment

Treatment of oily sewage in ports, terminals and oil depots

Ship and other oily sewage treatment

Suitable for filtration treatment of reuse and treatment of oily sewage and other oily wastewater circulation systems in the steel, metallurgical and coal industries;

It is suitable for fine filtration of large-volume oil field reinjection water, offshore oil platform produced water and heavy oil oil field thermal recovery boiler regeneration water treatment;

It is suitable for filtration and advanced treatment of cooling circulating water in power plants, refineries and petrochemical plants.

Walnut shell filter is currently the most effective means in major oil fields to improve crude oil recovery by reinjecting wastewater after treatment. It is also an ideal equipment for advanced treatment of oily wastewater in petroleum refining, petrochemical industry, steel and other industries.

This filter is a separation equipment successfully developed using the principle of filtration and separation. It uses oil-resistant filter material - walnut shells and has two control modes: automatic and manual. When filtering, the water flows from top to bottom, passing through the water distributor, filter material layer, and water collector to complete filtration. During backwashing, the agitator turns over the filter material, and the water flows from bottom to top, so that the filter material can be better cleaned and regenerated.

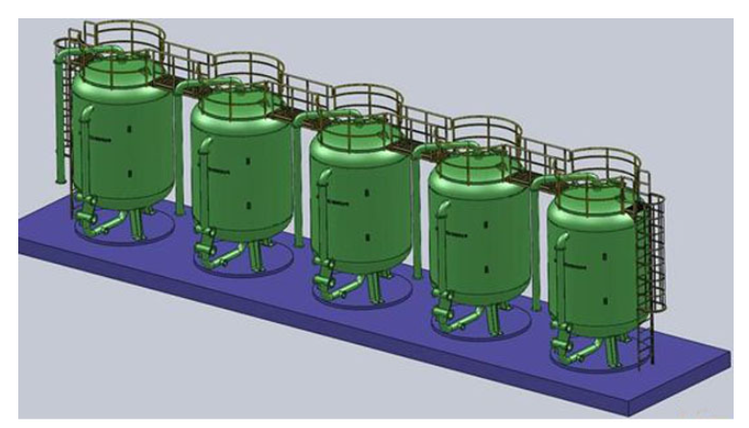

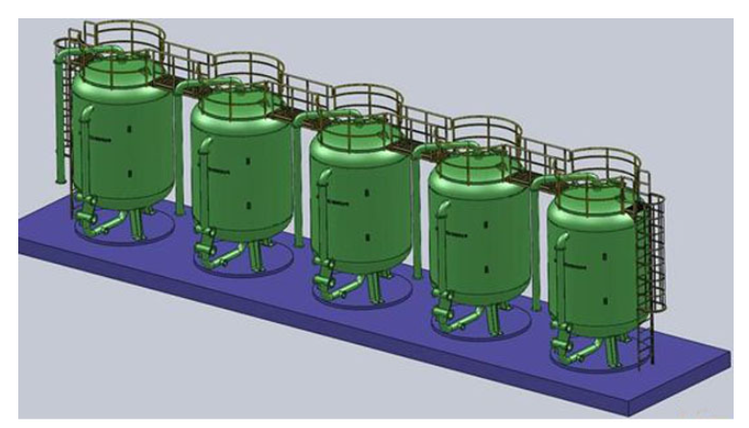

The walnut shell filter for oily sewage is mainly composed of a filtration system, a cleaning system and a control system. It is widely used in the treatment of oily wastewater from medium and high permeability oil fields, and can also be used for wastewater treatment in other industries. The equipment is easy to operate, has high filtration precision, large processing capacity, and clean filter materials.

The walnut shell filter uses specially processed walnut shells as the filter medium. It has strong adsorption capacity, and the filter material can be backwashed and reused. It has strong pressure resistance and stable chemical properties (not easy to dissolve in acid and alkali solutions). , high hardness. It has good wear resistance and does not need to be replaced for long-term use. It has strong ability to adsorb and intercept dirt, has good hydrophilicity and is resistant to oil immersion.

The characteristics of this filter material are that it directly uses pre-filter water for backwashing without resorting to air sources and chemicals. It has low operating costs, convenient management, low backwash intensity, good effect, the filter material is not easy to rot, is durable, and can be used according to water quality requirements. , adopt single-stage or double-stage series connection.

The difficulty of sewage treatment in the oil production plant system is relatively high. The water quality and water volume after the filter tank do not meet the system design requirements. If the water quality exceeds the standard, it will seriously affect the back-end sewage softening effect, affecting the quality and safety of gas injection.