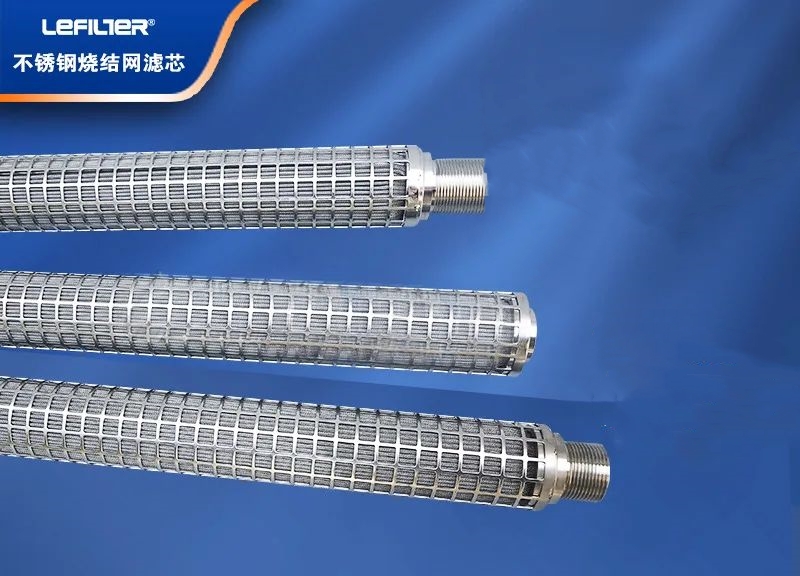

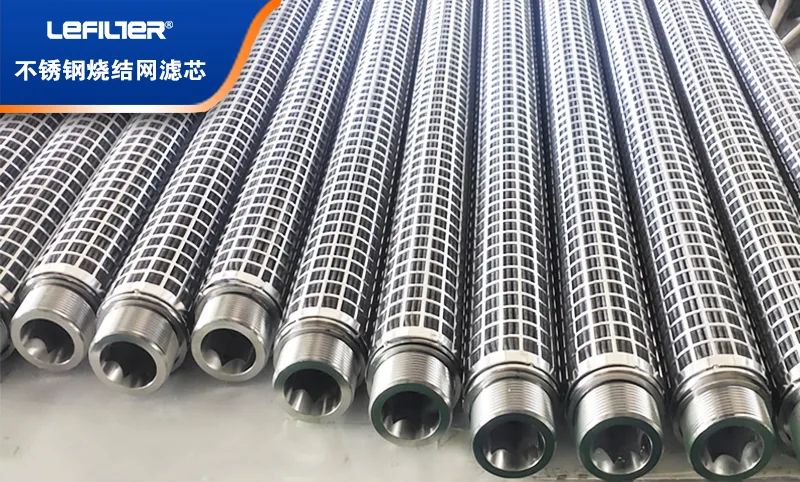

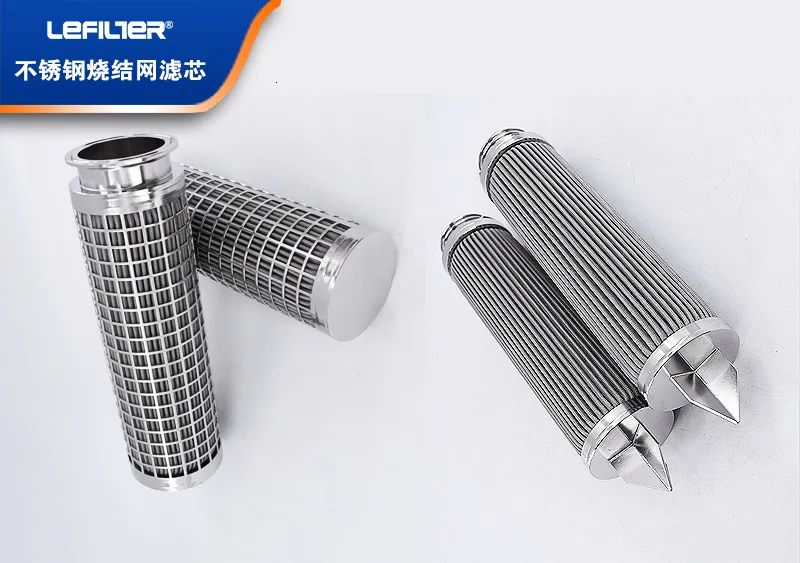

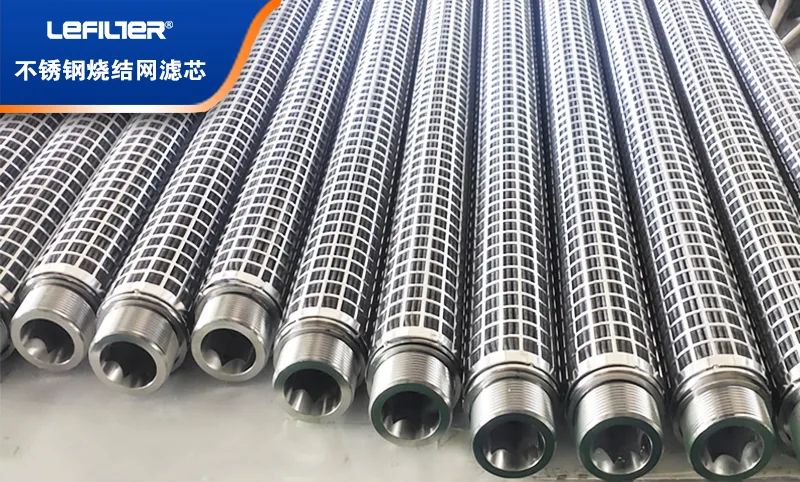

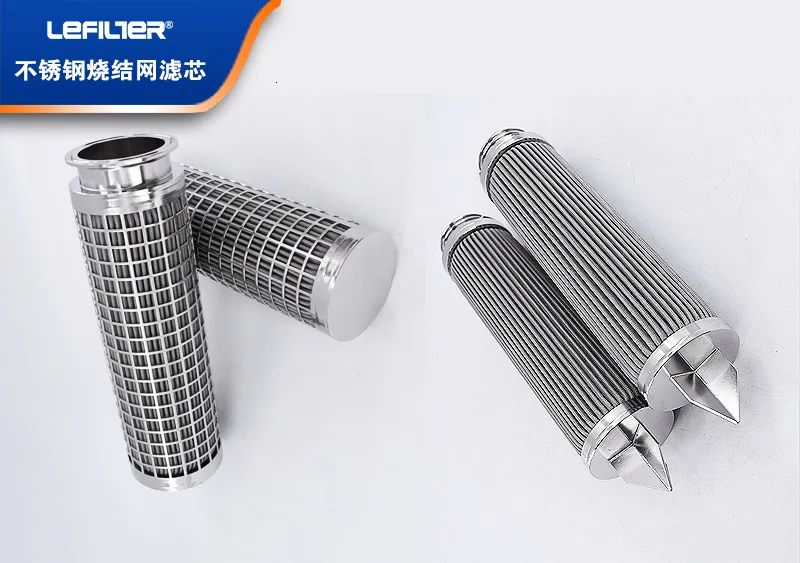

Stainless steel sintered mesh cartridge is a new type of filtration material with high strength and overall steel property made of multi-layer metal sintered mesh, using multi-layer stainless steel mesh through special laminated pressing and sintered by vacuum, with filtration precision up to 5um and temperature resistance up to 650℃.

Material

304/316/316L/304L

Hastelloy/C276/C22

904L/2205/2507

Duplex steel, customized for special needs

Connection method

226, 222. threaded, double port flat, single opening, tie rod, inserted, flange, quick snap

Skeleton

The outer diameter is about 60mm, the pressure is more than 0.3Mpa, it is recommended to increase the skeleton

Filtration direction

Outside in and inside out (fine mesh outside)

Inside in and outside out (fine mesh inside)

The filter element is generally outside in and inside out; the filter basket is mostly inside in and outside out, the pressure should be greater than outside in and inside out

Advantageous features

Corrosion resistance

Made of 304 or 316 stainless steel, the multi-layer filter material structure, with the coarse screen covering the fine screen, can filter the polluted fluid in layers and prolong the service life of the filter material.

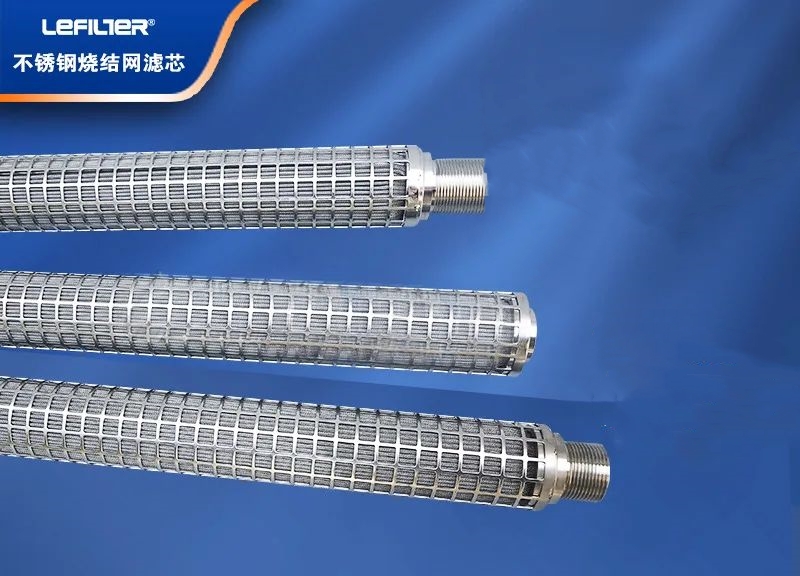

High strength

The flat-designed screen is simple to process and easy to clean, and the fusion-welded cartridge structure can withstand a working temperature of 650℃ and a pressure drop of 5kg/m/72.5psi.

Screen does not fall off

The industrial-grade folded sintered cartridge with strict structure will not shed fibers and will not be analyzed out.

Washability

The structure of the woven mesh can be repeatedly cleaned and regenerated for use, which is an efficient and stable filtration option.

The cartridge is mainly applied to the filtration of high-temperature steam and gas, and is also used in the following industries:

1. precision filtration of various hydraulic oil lubricating oil in the machinery industry.

2. Filtration and purification of various polymer melts in the chemical fiber and film industry.

3. Filtration of various high temperature and corrosive liquids in the petrochemical industry.

4. Pharmaceutical industry in the filtration of materials, washing and drying.

If you are interested in our product, please feel free to contact us at any time!