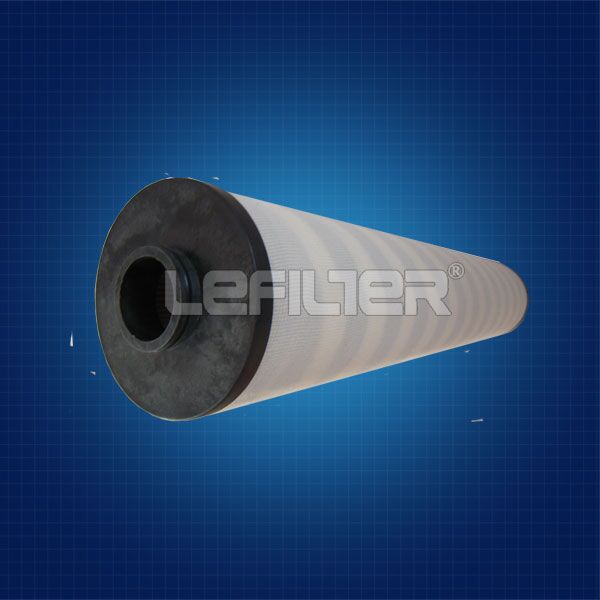

Facet Filter Element Fa-644-3A Coalescing Filter Element for Water and Oil Removal Filter Element

Introduction:The coalescing filter element has the dual functions of filtering impurities and condensing moisture from aviation kerosene. It is an important functional component of the precision filter. It can meet the needs of various precision filters used in fixed or mobile refueling facilities.

We're here to help:

Easy ways to get the answers you need.

Product parameter:

Our company's polymer cores are made from various materials such as turbine oil, transformer oil, aviation fuel, gasoline, and oil Diesel, tar, naphtha, etc. can also be used for their carbon oxygen conversion when using different accumulating media Class of compounds such as liquefied petroleum gas, benzene, toluene, xylene, isophthalic acid, polyphenylene, cyclohexene, etc

The dual function of filtering impurities and coalescing water in substances such as alkanes, cyclohexanones, and cyclohexanones is to Important functional components of filters. Agglomeration filter can be used in both fixed and mobile devices

The need for various aggregation filters.

| FA-614-1A | FA-628-1A | FA-628-1A | FA-614-2A | FA-628-2A | FA-644-2A | FA-614-3A | FA-628-3A |

| FA-644-3A | FA-614-5 | FA-628-5 | FA-644-5 | FA-614-5CIF | FA-628-5CIF | FA-644-5CIF |

The company mainly produces and sells aviation coalescing filters, aviation separation filters, aviation pre-filter filters, natural gas coalescing filters, natural gas separation filters, and natural gas pre-filter filters.

The products are made of imported HV glass fibers, multi-layer composite fibers, polyester fibers, Teflon nets, polypropylene, sintered fiber tubes, etc. The products feature high filtration accuracy, low initial pressure difference, strong flow capacity, large pollutant retention capacity, and long service life.

Their main performance indicators have reached the international standard and can replace similar imported products. The products are widely used in various fields such as petrochemicals, power plants, metallurgy, mining, oil refining, cement, electronics, tobacco, fertilizer, food, pharmaceuticals, shipbuilding, and wastewater treatment.

Our factory has a professional design and production team with excellent quality and efficient performance. The products are sold well in the domestic market and are also exported to many countries and regions.

The aviation polyester fiber coalescing filter element FA-644-5CIF is produced with high-quality coalescing materials to ensure that the filter element has excellent technical performance, quality and large filtration capacity, as well as long service life.

The coalescing materials are of a composite structure and adopt layered coalescence, which gradually enlarges the tiny liquid droplets, thereby significantly enhancing the filter's dehydration capacity and working life.

The coalescing materials are all consolidated with resins and processes, and will not experience short circuits or fiber detachment even under high flow rates and strong pressure pulsation impacts.

It is resistant to oil and water adhesives, ensuring that the filter element's ends are firmly and reliably bonded, and the filter material seams are firm and tight.

All metal materials of the filter element have undergone anti-corrosion surface treatment, which can ensure that the filter element is not corroded during its effective lifespan and normal storage period.

The coalescing materials are all consolidated with resins and processes, and will not experience short circuits or fiber detachment even under high flow rates and strong pressure pulsation impacts.

It is resistant to oil and water adhesives, ensuring that the filter element's ends are firmly and reliably bonded, and the filter material seams are firm and tight.

All metal materials of the filter element have undergone anti-corrosion surface treatment, which can ensure that the filter element is not corroded during its effective lifespan and normal storage period.

Please fill in your procurement needs and contact information