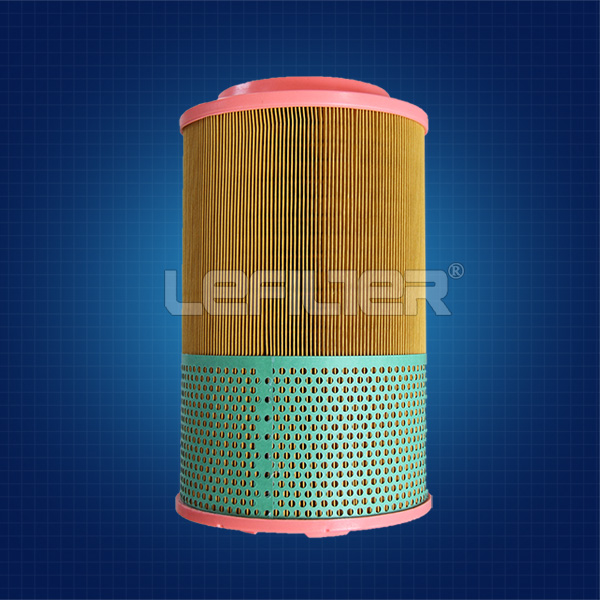

Atlas Copco Compressor 1625480000 Air Oil Separator Filter Element 1625481101

Introduction:oil air separator technical parameters: 1, filtration accuracy is 0.1μm 2, the oil content of compressed air can reach 3ppm or less 3, filtration efficiency 99.999% 4, the service life can reach 3000-6000h 5. Initial pressure difference: ≤0.02Mpa 6.The filter material is made of imported composite fiber

We're here to help:

Easy ways to get the answers you need.

Product parameter:

Atlas oil and gas separator is a key part of Atlas air compressor. Its performance will directly affect the effective power, fuel consumption and output airflow stability, cleanliness, and dryness of the compressor. High-quality oil separators, when installed and used correctly, can not only ensure the high quality of compressed air, but also ensure a considerable service life.

Commonly used Atlas oil and gas separator filter elements are divided into A. External type (spin-on like an oil filter) B. Built-in type (1. The flangeless type is divided into one end and two ends. There is a flanged sub-flange No holes, holes, gaps, etc.).

The compressed air from the Atlas air compressor entrains large and small oil droplets. The large oil droplets are easily separated by the Atlas oil and gas separator, while the small oil droplets (suspended oil particles) must pass through Atlas. The micron glass fiber filter layer of the oil and gas separator filters.

We use the most advanced anti-corrosion and high-efficiency microfiber agglomerated material as the filter body. The filter bed of the system filter element is composed of a pre-filter layer, a microfiber layer, a support layer, a filter layer and a gravity sedimentation layer to make the compressor output air The solid particles above 3μm in the middle can be filtered out, and the very small oil-water vapor dissolution of about 0.01-1μm is condensed into larger oil droplets when passing through the filter element, which accumulates at the bottom of the filter element, and then passes through the recess at the bottom of the filter element. The oil return pipe siphons and returns to the lubrication system so that the compressor discharges more pure, oil-free compressed air.

| 1625481100 | 1613901400 | 1613900100 C1140 |

| 1625481101 | 1612386900 (2901003000) | 1619126900 C1450 |

| 1625481150 | 1625775400 | 1613872000 |

| 1625481151 | 1613750200 (2901034300) | C1250 |

| NS100140 | 1613750201 (2901034300) | 1613740700 |

| SPA50070 | 1613692100 (2901000401) | C16400 |

| 1513033700/2903033701/2903033700/6211472650 | 1622007900 (2901077900) | 1613740800/2901043100 C20500 |

| 1513033701/1513033700 | 1622005499 | 1613950100 C25740 |

| 1613610500 | 1622007901 | 1622185501/1622100000 |

| 1614727300 | 1622051600 (2901077901) | 1613800400/2901043100 C23610 |

| 1619622700 | 1622314000 (2901162600) | 1613950300 C25860/1 |

| 1614874700 | 1613688000 (2901021300) | 1030107000/1030104000 |

| 1202804002=1202804000=1092035894 | 2901021301 | 1030097900/1621054799 C36840/1 |

| 1202804092=1202804002 | 1613839700 (2901056600) | 1621574200 |

| 1622365280 | 1613839702 (2901056602) | 1630040799 |

| 1613610590/1613610500 | 1613839701 | 1630040699 |

| 1625840000=1622314200 | 1622365200 | 1621574300/1621054600/99,1621009400/1627009499/1635040700 |

| 1625752600 (2903752600) | 1622385200 | 1635040700 |

| 1625840200/1625840280 | 1625752500/2903752500 | 1621574399 |

| 1622365280 | 1627411010 | 1625165490 |

Please fill in your procurement needs and contact information